There’s nothing like a fast turn around, high stress project to showcase the model maker teamwork that KiwiMill has developed into a unique style of doing business.

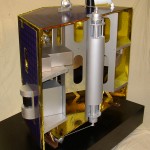

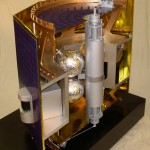

With less than two weeks to produce two 1:10 scale helicopter models, KiwiMill model makers have relied heavily on their well-balanced skill sets and even keeled approach to working together. Everyone has come together with their individual talents – CAD drawing, CNC programming, 3D printing, molding and casting, hand finishing, spray booth application and masking.

Beyond the tight time frame there has been a long anticipated, but still disruptive, employee exit, multiple machinery break downs and the usual minor shop mishaps and supplier logistics. Our model makers have dug deep into their skill sets, overcome the set backs and expanded their abilities as a team.

We are nearing our deadline, and every model maker and programmable machine are cranking out parts and assembling and finishing them. The CNC mill is cutting tails and fins. The 3D printer is growing rotor parts. The CNC router is finishing up the final body half.

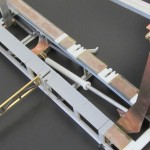

Meanwhile model makers are casting rotor blades, sanding tooling board and ABS, custom jigging the shipping crates and gluing together model parts. Everyone is looking for where they can help – all with the singular goal to produce 2 world-class models for an upcoming trade show.

Yes, there have been long nights, and a weekend full of overtime coming up. But everyone is committed to the project and highlighting the teamwork that makes these miracle jobs a reality at KiwiMill. Best of all, they do it without even realizing it. I’ve noticed, though, and I’m proud to work here with them.