Painting is Essential to Model Making

One of the more obvious features that sets great models apart from mediocre ones is the paint job. Everyone notices it. A model makers expertly applied paint job doesn’t automatically make a model high quality, but you won’t achieve model perfection without one.

A lot goes into the painting process. Even though it is often thought of as a finishing touch, it’s actually given a good deal of thought early on in a model build. Right at the beginning, during the brainstorming and design phase, consideration is given to the paint colors that will be needed for the different parts. It helps determine the order that the model will be assembled in. Parts are generally painted before being assembled, not after. So it’s not a final step in the process after all.

What Kind of Paint Is Used?

There are different types of paints for different projects. Our model makers use enamel, lacquer, epoxy, automotive and model paint. Models need paint that looks good, stays on and is quick drying. Less consideration is given to the hardness of the paint as most models are not subjected to outdoor elements, or scrubbed clean on a regular basis. Paint has two, sometimes three, characteristics that determine how it will perform: pigment, binder and solvent. The pigment will determine the color hue, the binder is the vehicle that sticks the color to the model and the solvent affects the flow or spread-ability.

Once a particular paint is chosen, the model is first given a coat of primer. Primer is a grey, sand-able substance that helps the paint stick to the model. It is flat rather than glossy in texture in order to show all the details of the model, and point out any scratches or blemishes that may need to be filled or sanded out. Sometimes the primer itself will smooth out light scratches, other times a spot putty is applied to deeper flaws in the surface. When primer has been applied, filled in and sanded the model is perfectly smooth and ready for a coat of paint.

How Is The Paint Applied?

The delivery method of the paint is most often an air brush, HVLP (high volume, low pressure gun), or spray can. Most paint is applied in some kind of mist form. Rarely is a brush used, except for the tiniest details. Masking is used to cover parts of the model that are not ready for painting. Special tape is used for this purpose. While applying paint, it’s also important to know how different paints will interact. Some types of paint will have a volatile reaction with each other depending on the type of solvent that is used in them.

Once the paint has been applied with an expert hand and eye, it needs to dry properly. While some paint will be dry to the touch almost immediately, the surface underneath may still be damp. A model may seem dry when the solvent in it hits the air and evaporates, but curing is the polymerization of the paint binder (a chemical process that may take much longer). Ideally a freshly painted model should sit for a couple of days before packing or wrapping for shipment.

The paint job on a model has a huge impact on its appearance and like-ability. It makes sense that it is given important consideration from the onset of a project, all the way to its finish.

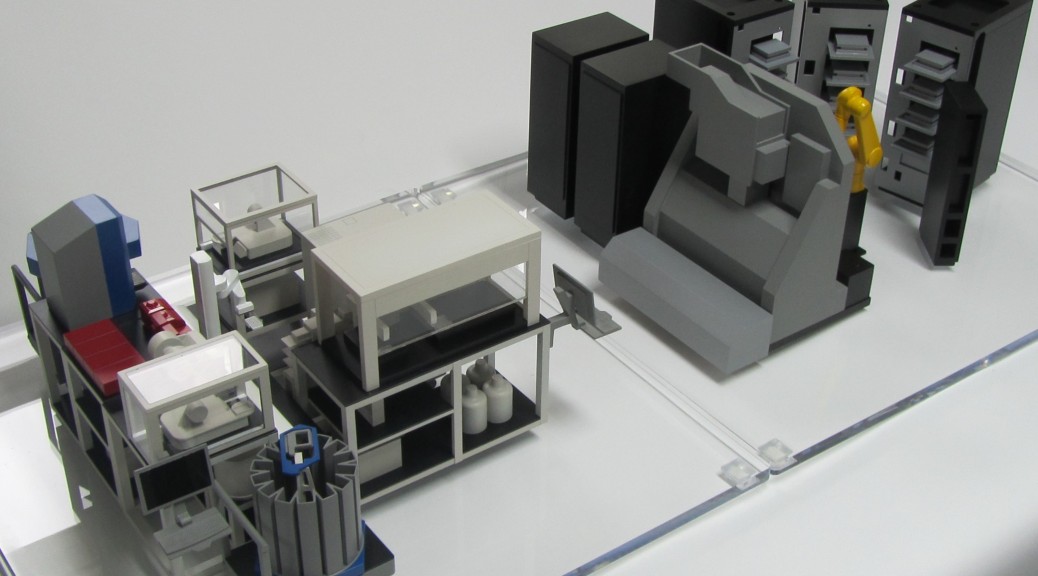

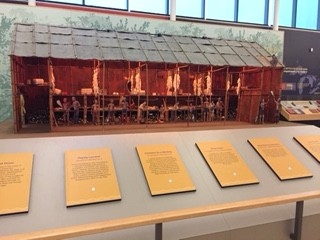

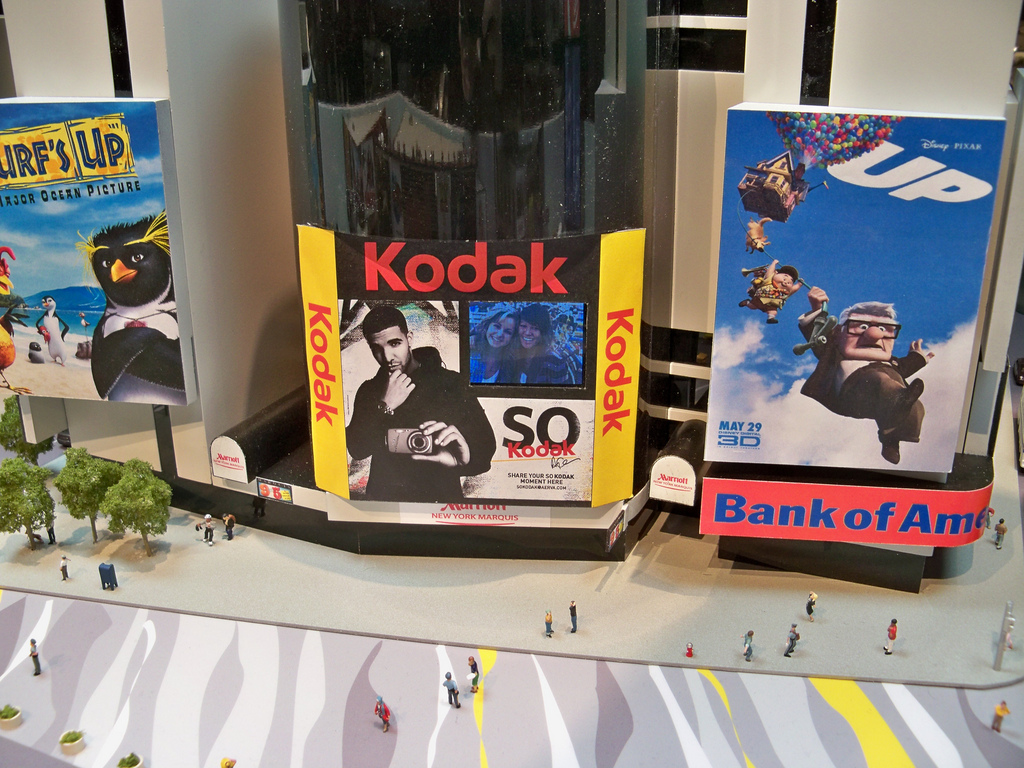

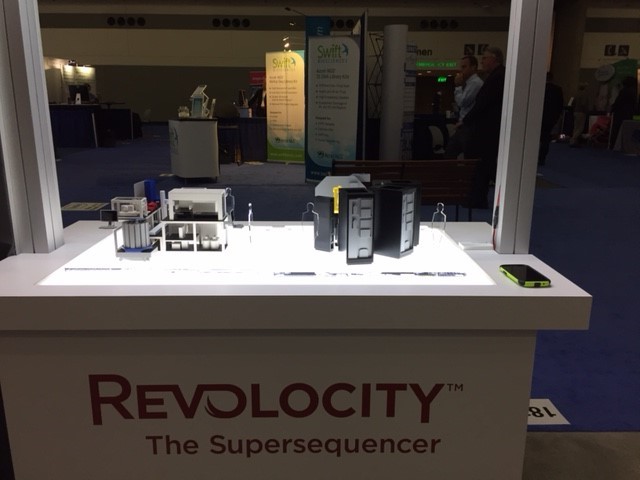

Check out these Before / After Pictures: