A Model Maker is someone that most people don’t know a lot about. People tend to think of model making as either as a layman’s hobby or a skill that has been replaced by computers. Neither view is quite accurate. Model Makers are a group of professionals that find viable work in industries such as trade show, product design & development, sales and marketing, entertainment, military, architectural and museum – to name a few.

Model makers often start out as hobbyists, particularly in their youth. Plenty have found their initial love of taking things apart and re-assembling them, often in new, creative ways, as a gateway to model making. One of the main differences between the model making hobbyist and the professional model maker, is deadlines. While hobbyists may have advanced skill sets, and even generate income from their craft, typically they do not have the same strict deadlines as professionals do.

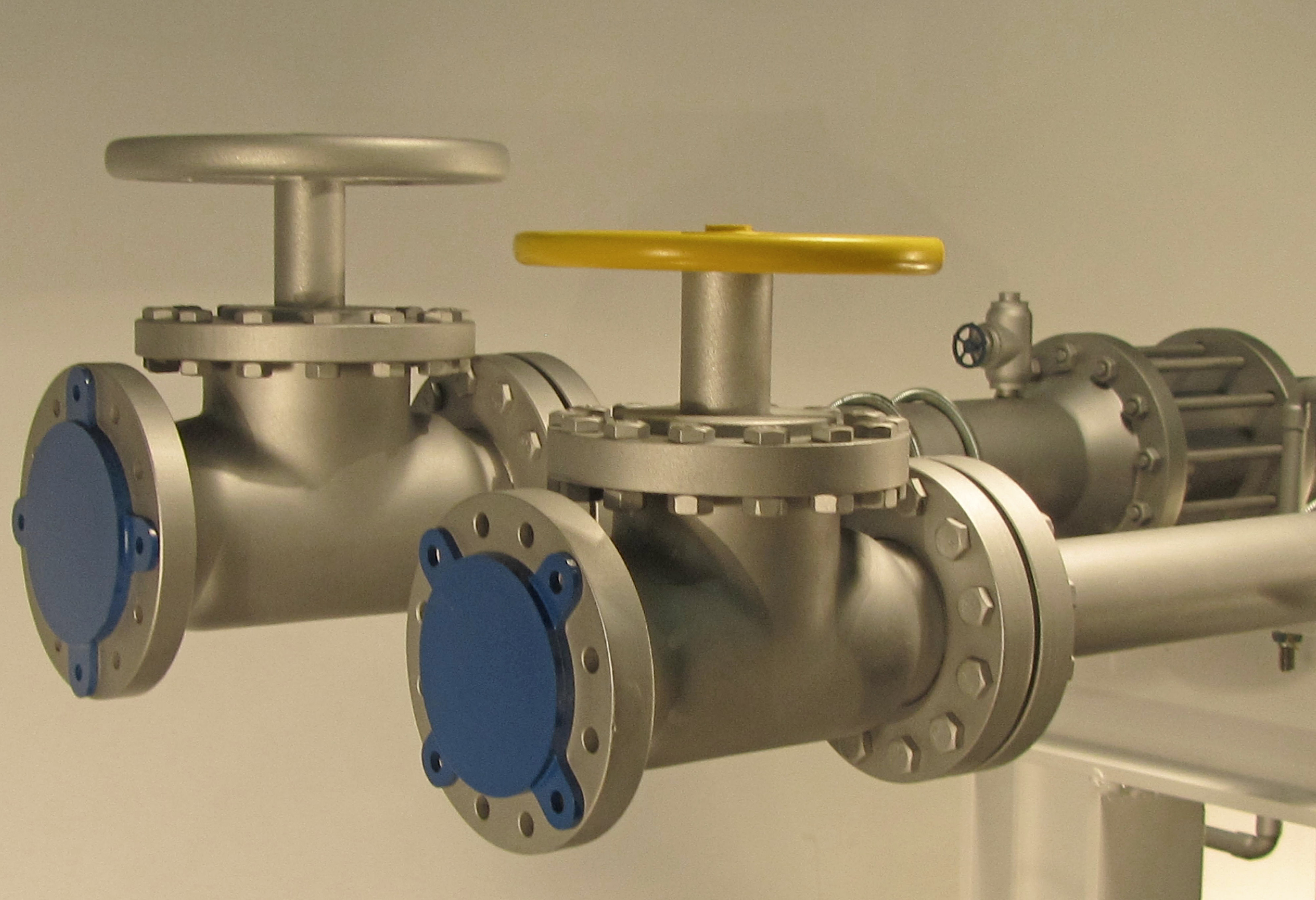

Modern model makers often work under tight time constraints. They might be creating a model of a product to ensure its integrity before it goes to production. A scale model might be used in an upcoming trade show to sell a new idea. An architectural model might be needed for the opening of a developer’s sales office. Or a museum may be looking for a showpiece for an upcoming exhibit installation. In most of these instances, there is a sense of urgency, and professional model makers are used to putting in extra hours to meet strict deadlines.

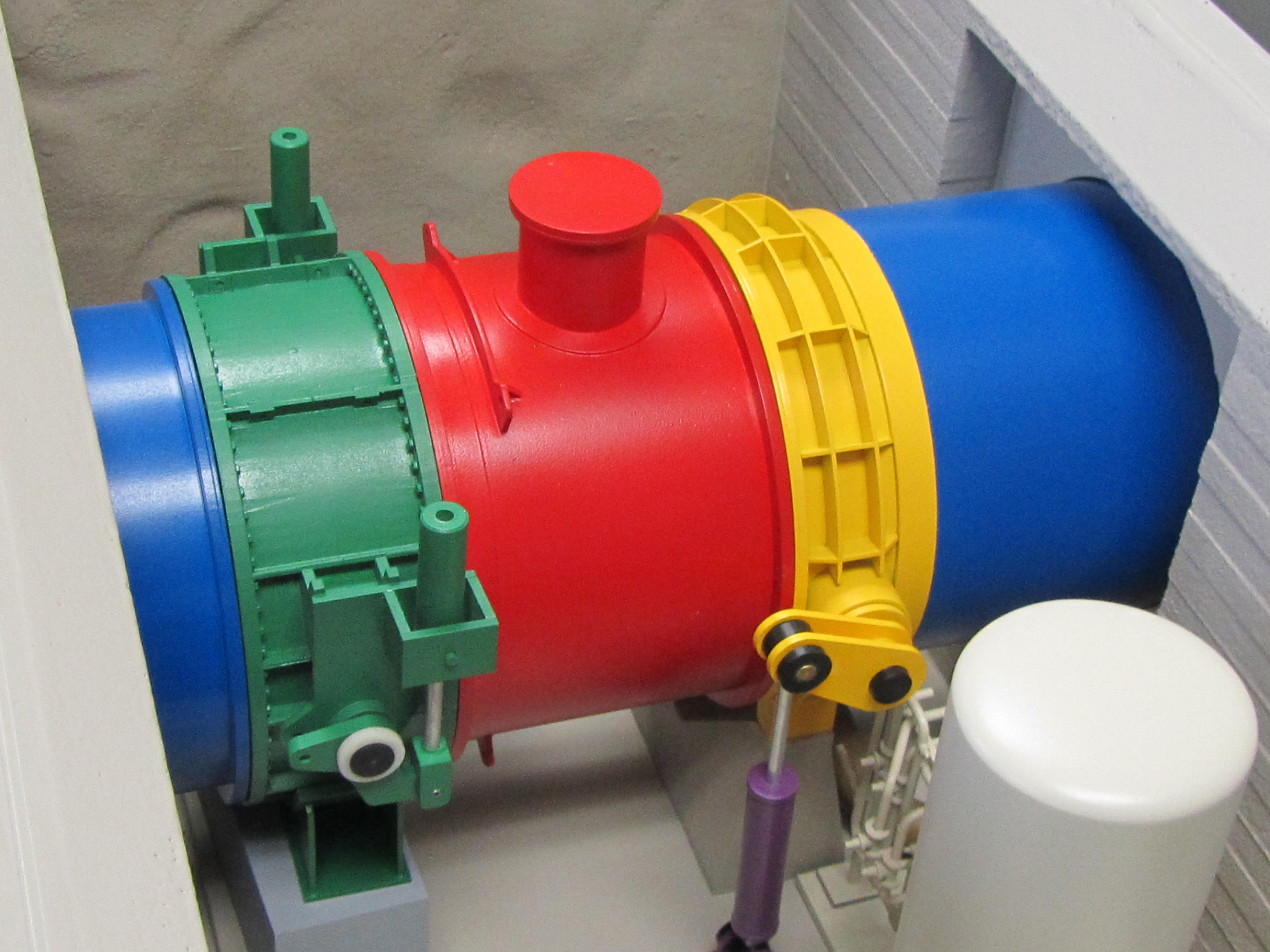

While technological advances, particularly in the area of 3D drafting, CNC machining and rapid prototyping have changed the modern model shop, they have not replaced the need or desire for 3D physical representations. Rather, computers have enhanced the profession in surprising ways. With the advent of new technological tools, scale models are becoming more accurate, detailed and economical than ever before.

Of course that has some people wondering if the artistry and craftsmanship of a master model maker still exists, or is even necessary. Increasingly, it is the combination of Old World techniques and modern advances that set great scale models apart from the competition. Model shops that are producing exceptional models have found that perfect blend of old and new processes.

Successful model makers have a somewhat contradictory set of abilities. They need a creative mind to envision/design the finished model, but also be a logical thinker who can work through the challenges of each build. They are mentally focused on construction, while remaining very flexible in their approach when it needs to be altered midway. Model maker’s artistic sensibilities help give a model visual appeal, capturing the essence of an object, not merely replicating its structure. On the other hand, the engineering/logical side of a model maker understands and solves technical issues that come up. Part analytical and part fanciful makes for an interesting mix.

Besides being of a certain mind-set, a person wanting to become a model maker needs experience working with his or her hands. Model makers use a wide variety of materials such as plastic, wood, metal, glass, rubber, plaster and foam. The developing model maker learns the properties of these materials and how they interact with each other through direct contact, while also honing dexterity and attention to detail. Nothing replaces the knowledge and skills gained from building objects from scratch.

In addition to these skills, the modern model maker should have a working knowledge of CAD, as well as free hand drawing ability. CNC machines are great additions to a model shop, as well as 3D printers. These require the computer skills necessary to read, draw, translate and transmit information to machines that can print, route, mill, etch or carve parts to supplement what a model maker hand builds. Use of these machines increases the accuracy and speed in which a model is produced.

Experience using tools associated with model making is also helpful. Tools like a table saw, welding equipment, paint gun, sanders, lathe, mill, band saw, sand blaster, drill press and shear might all be used by model makers. This is in addition to hand tools like calipers, X-Acto knives, sand paper, files, dental picks and paint brushes. Not only responsible for fabricating various designs, it’s worth noting that model makers build the furniture-quality bases for models to sit on or in, as well as the crates the models are shipped in.

It’s easy to see that there is no one path toward a career in model making. While advanced degrees and certificates in model making are not all that common in the U.S., they do exist. Other model makers have degrees in Industrial Design, or Fine Arts. Some model makers have engineering or electronics backgrounds that help particularly with models that have special effects like movement, lights or sound. Still other model makers found their way to the profession through crafts backgrounds or carpentry. With any background, it helps to work under a Master Model Maker to absorb their experience – the depth and breadth of knowledge necessary to tackle the wide variety of modeling techniques that exist.

It takes a special someone who can visualize an idea or 2D representation and transform it into a fully realized three-dimensional object. While there are not a huge amount of career opportunities in model making, job satisfaction in the industry is high. The work is varied, challenging and satisfying. It’s a great fit for a mind that is creative yet logical, and for people who simply must do something with their hands.