Occasionally I like to take time out to acknowledge the work that model makers do, both here at KiwiMill and elsewhere. I spend most days in a support role at the model shop and I tend to take for granted what takes place every day. Then I talk to someone outside of the profession and realize it’s a pretty unique job.

Custom model makers build something different for each project they take on. In the shop right now, we have a hand-built 1:14 construction vehicle, a display stand with printed coats of armor, an oil well site, heating element models, a bread board design of a toy, a propane tank model and a vapor absorption machine.

Many of the models are for trade show use, sales or development, some for personal display and still others for teaching and instruction. Each one comes with its own unique needs that dictate how the model will be built.

Our model makers figure out the purpose of each model and then decide from there how to go about the build. Sometimes our model makers are given engineering drawings, sometimes simply a photograph. Often our model makers take pictures themselves of the real life object they need to replicate. Recently we had the real life object driven right to our parking lot for pictures!

Model makers need to know enough about each product, process, machine, landscape or structure to replicate what it looks like. Often they need to know what it looks like on the inside, such as with a cutaway model, and sometimes they must make it operate like the real item. That’s a lot of knowledge to accumulate for a 6 week build. Only to start all over again from scratch with the next project.

Getting to know each real word object intimately, in a short amount of time, is just one aspect of the model maker’s job. Engineering the model comes next. It’s not as simple as rebuilding it exactly as it was designed at the manufacturing stage. A model is built using its own unique principles. It is a representation of a real life object, not an exact design.

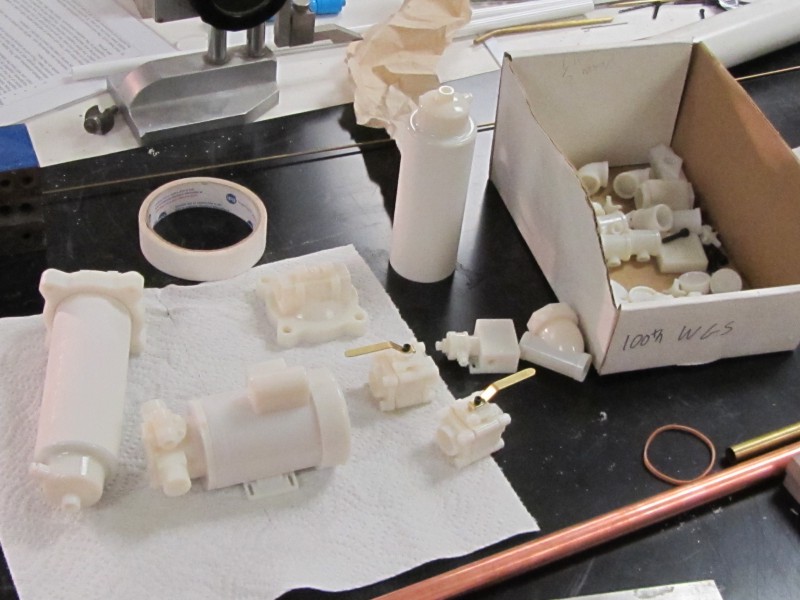

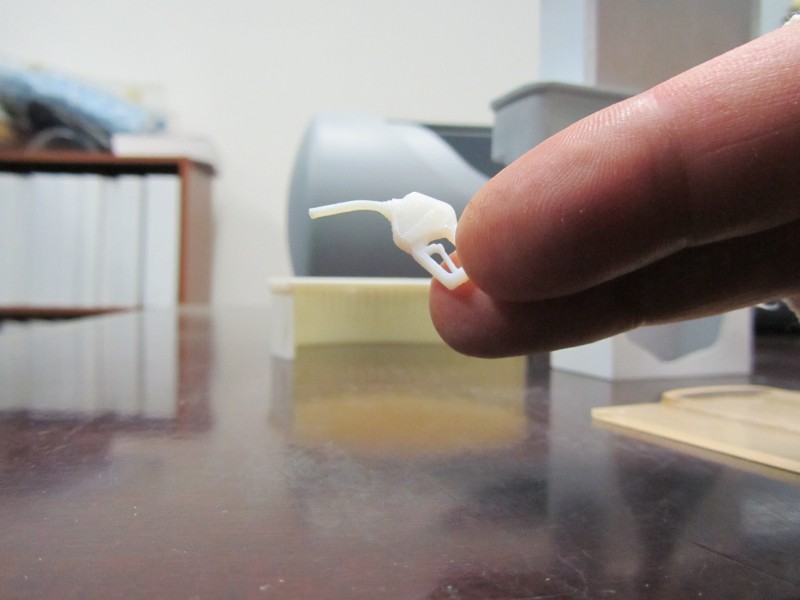

After the model design stage, materials and fabrication methods need to be chosen. A model maker, again, knows a lot about a wide range of materials and their properties. The same goes for fabrication methods. The tools in our shop are incredibly varied. CNC routers mix with table saws; 3D printers exist alongside a drill press and a lathe.

Knowing how to operate machines and hand tools safely and effectively is important. Being aware of how different materials react to each other – and the solvents used to bond them – is crucial. Once built and assembled, a well stocked paint booth and expert application of pigment allows our model makers to apply the finishing touches to a quality model.

It makes for exciting and varied work. Model makers have a willingness to tackle new projects. They need to be able to apply previous experience, and lessons learned, to a new challenge. Model makers are adaptable and resourceful.

Even as I write this, I can hear two model makers discussing electrical engineering for one of their latest projects that requires remote control movement. Today I am thankful to be in a work atmosphere with so much talent, knowledge and willingness to learn new things.