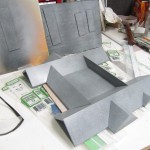

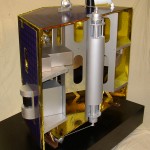

Recently KiwiMill built an architectural model of a campus building expansion. The donor was presented with this scale model of the school building as a thank you. Having an architectural model made of new real estate can be an effective way of showing appreciation for a donor, along with naming rights of the space.

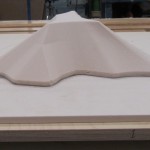

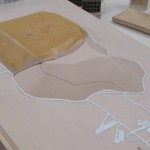

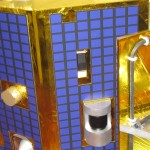

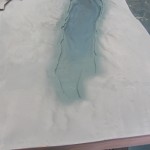

This particular architectural model was made mostly from precision laser cut plastic. It has a unique brick texture that has been spray masked on to match the particular pattern used by the college.

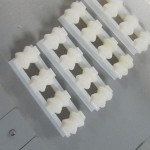

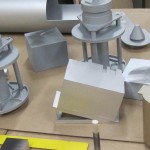

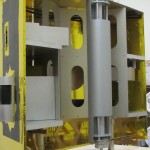

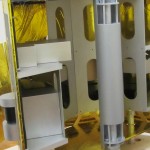

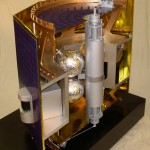

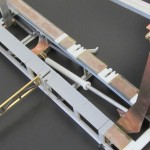

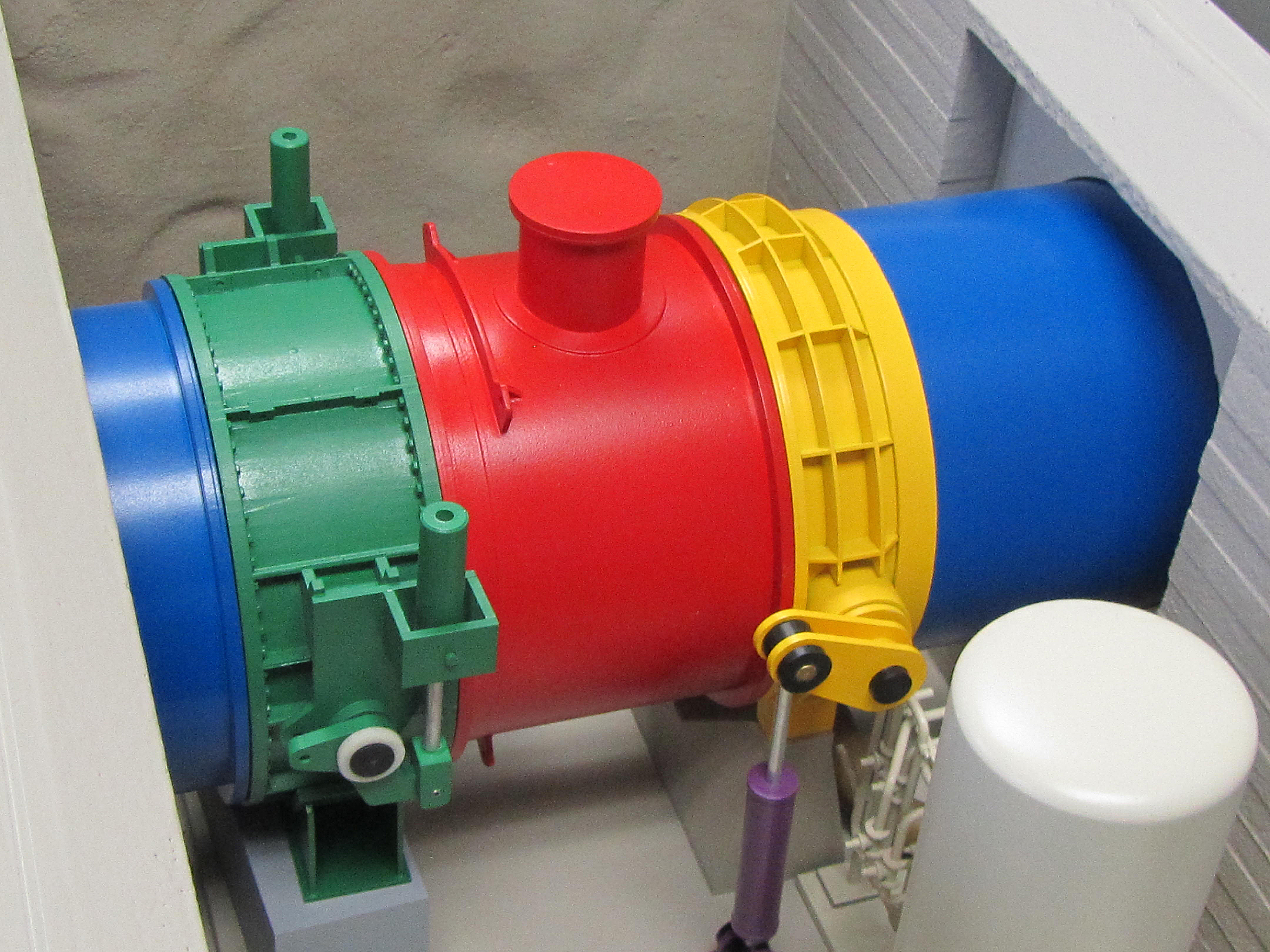

The architects on this project wanted the option of showing the various HVAC parts that are commonly found on the roofs of buildings. While they are not often depicted in architectural models, KiwiMill built the scale HVAC equipment and provided the pieces loose, so they can be added to the model if desired.