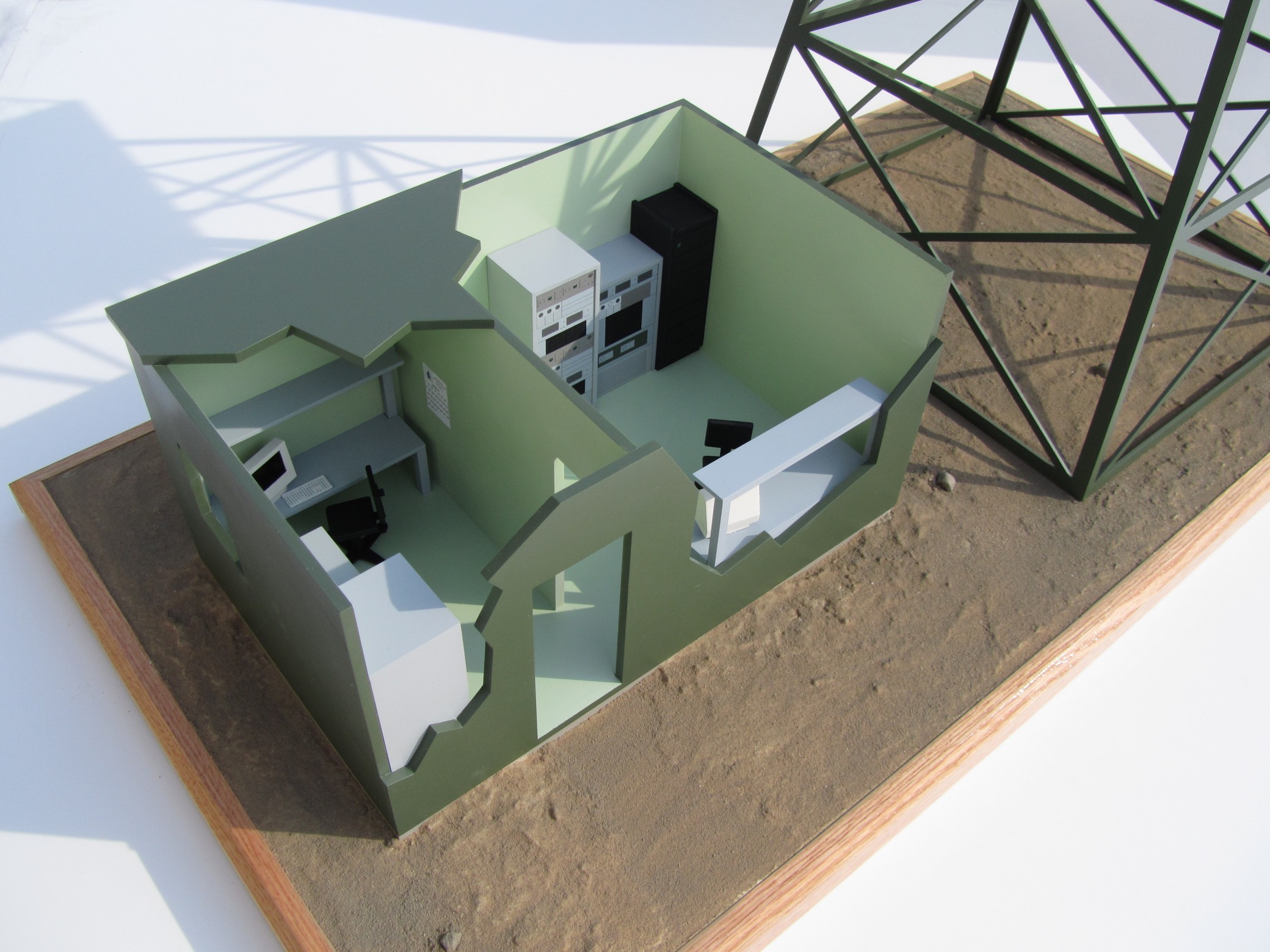

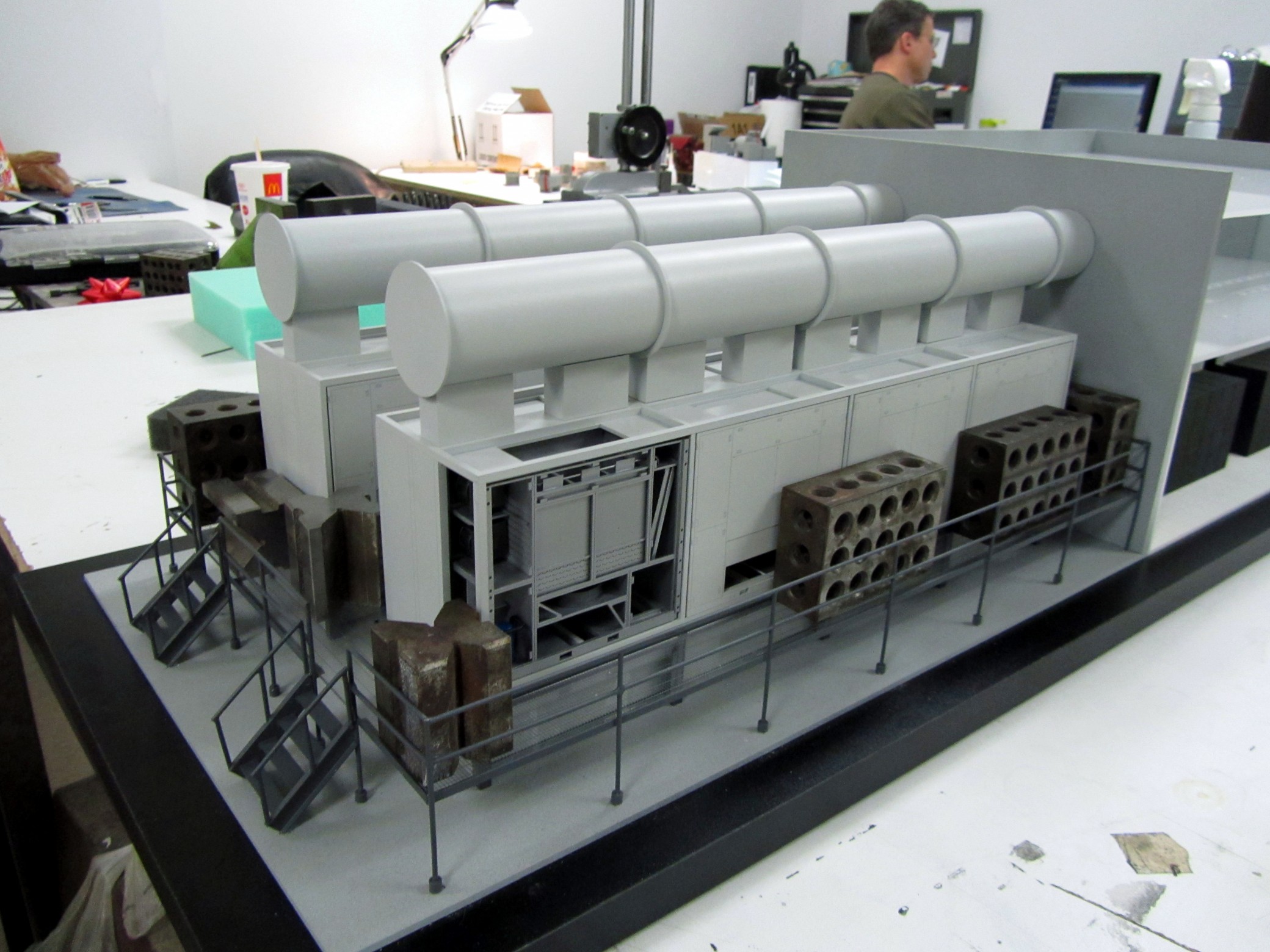

Our shop has been working on a project that involves extensive use of 3D mechanical drawings. The scale model, an asphalt plant, will be 7 feet tall when completed. The size and structure of the scale model requires it to support its own weight and traditional model making materials would not be appropriate. Sheet metal will be used instead, and the parts need to be sent out of the shop to be laser cut and bent.

Model makers typically design a project as they build it, problem solving, adjusting and refining their techniques as they go. As craftspeople, they can transform a rough idea into something both accurate in design and beautiful to behold. The sheet metal parts are being sent to a laser cutter unfamiliar with the project’s nuances, so more precise, documented dimensions are needed.

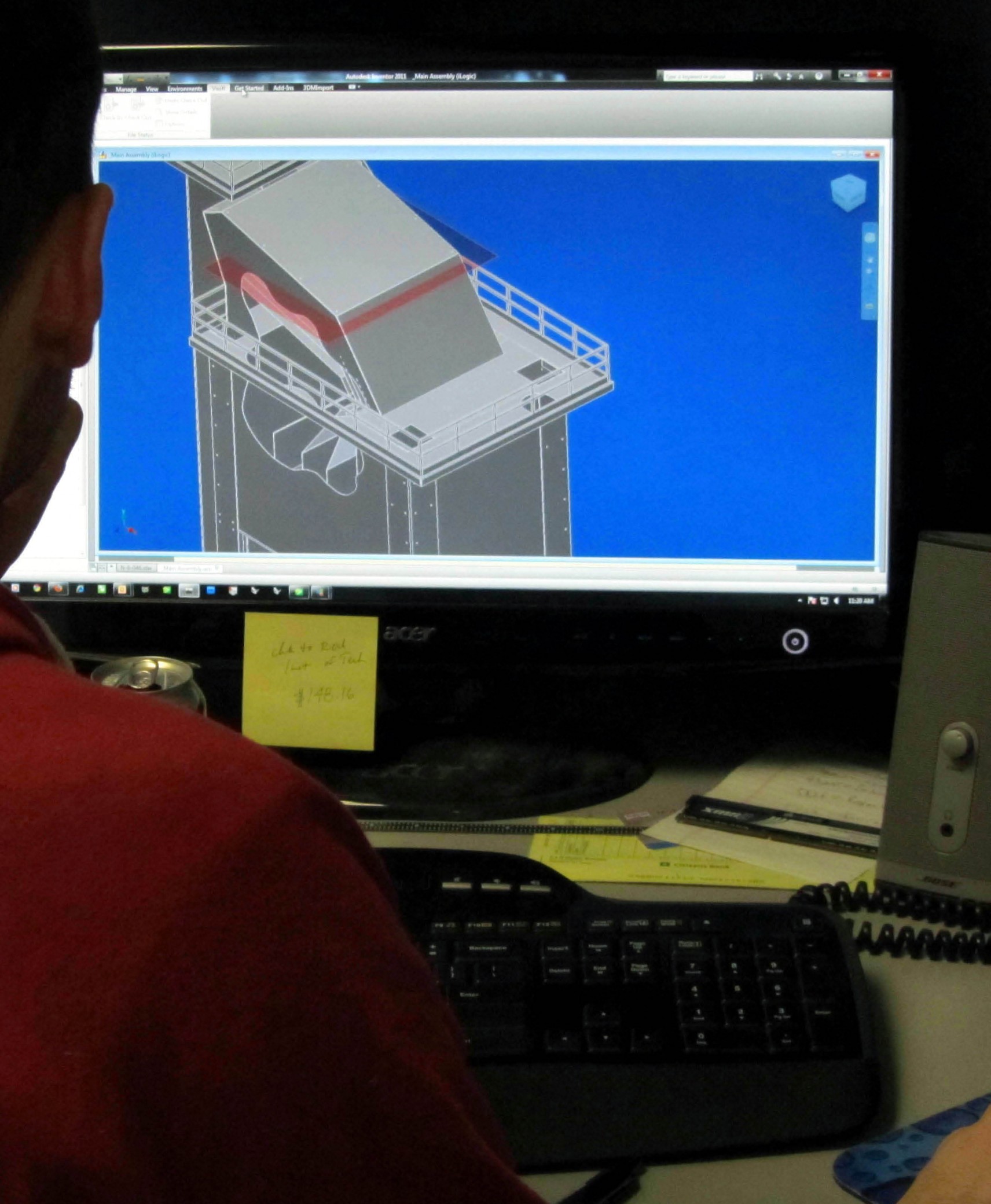

Using a program called Autodesk Inventor, our model makers have drawn up the sheet metal parts on the computer to be sent to the laser cutter. Then the parts will be bent next door at Clad Industries. The finished pieces will arrive back to the model shop for assembly and detailing. Check back for pictures of the finished scale model!