One fabrication technique that is not often associated with model making is welding. While styrene plastic and glue are staples of some model designs, many more are made out of metal for stability, longevity and appearance. One way to fasten metal model parts to each other is by welding, or a similar technique: soldering. While not every model maker is skilled in this trade, it’s helpful to have the training and equipment on hand in a professional model shop.

One fabrication technique that is not often associated with model making is welding. While styrene plastic and glue are staples of some model designs, many more are made out of metal for stability, longevity and appearance. One way to fasten metal model parts to each other is by welding, or a similar technique: soldering. While not every model maker is skilled in this trade, it’s helpful to have the training and equipment on hand in a professional model shop.

Welding is the process of bonding parts together by applying heat to two pieces of metal and melting them together along with a filler material to form a strong joint when cooled. Soldering is similar but does not actually melt the work pieces themselves, only the filler material between them which has a lower melting point, thus requiring less heat application.

Types of models that may need welding or soldering application vary. If a model needs to hold up to heavy handling by the client it might be considered a good candidate for brass, sheet metal or stainless steel. A more delicate material would not hold up to rigorous use. As with most models, the purpose or intended use informs the materials and fabrication techniques involved.

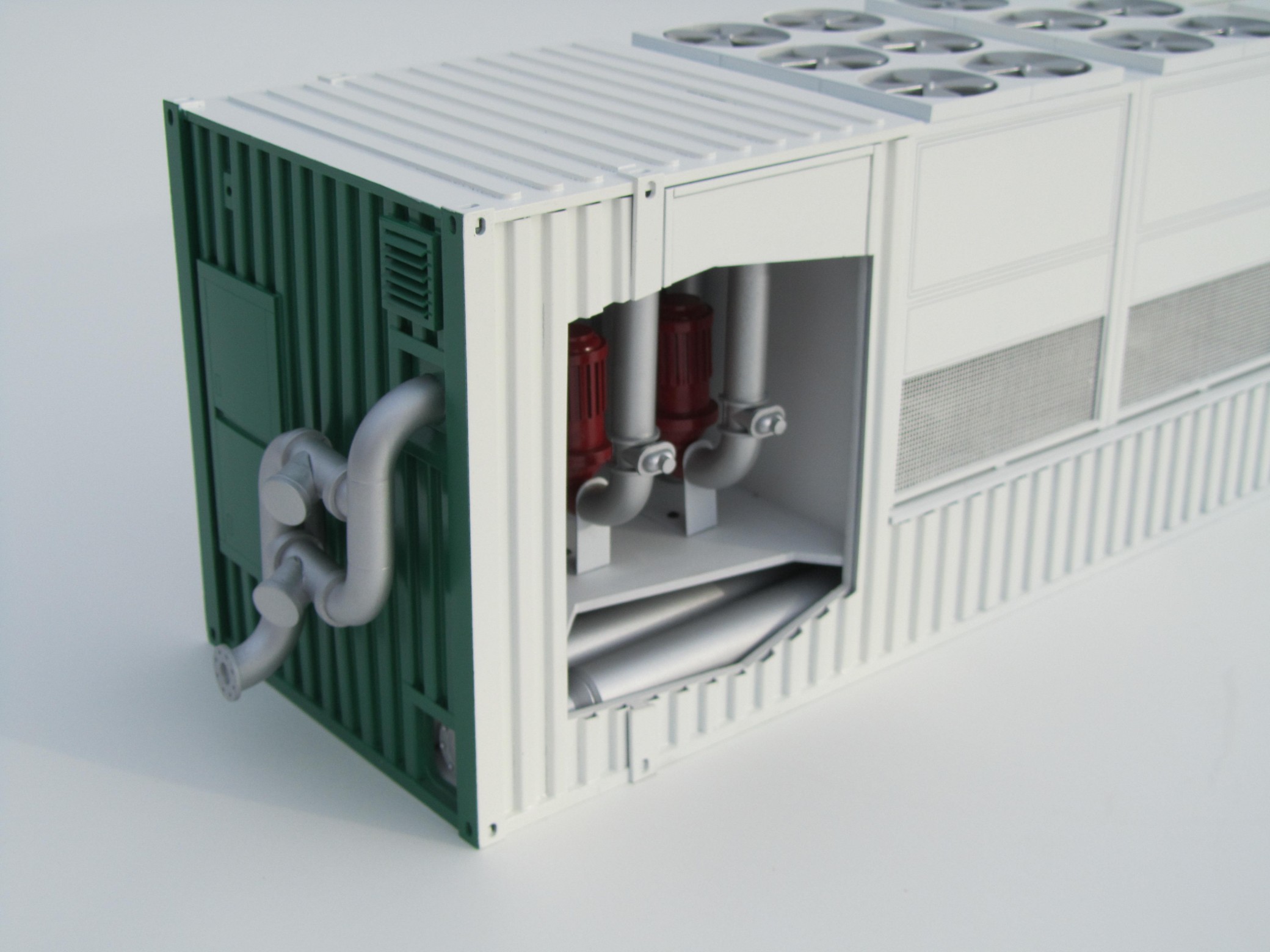

Currently KiwiMill has two models in the shop that required welding. One is a large-scale model of an asphalt plant and the other is a model of an expandable shipping container. One of our model makers has apprenticed with another in-house master welder to complete these projects.