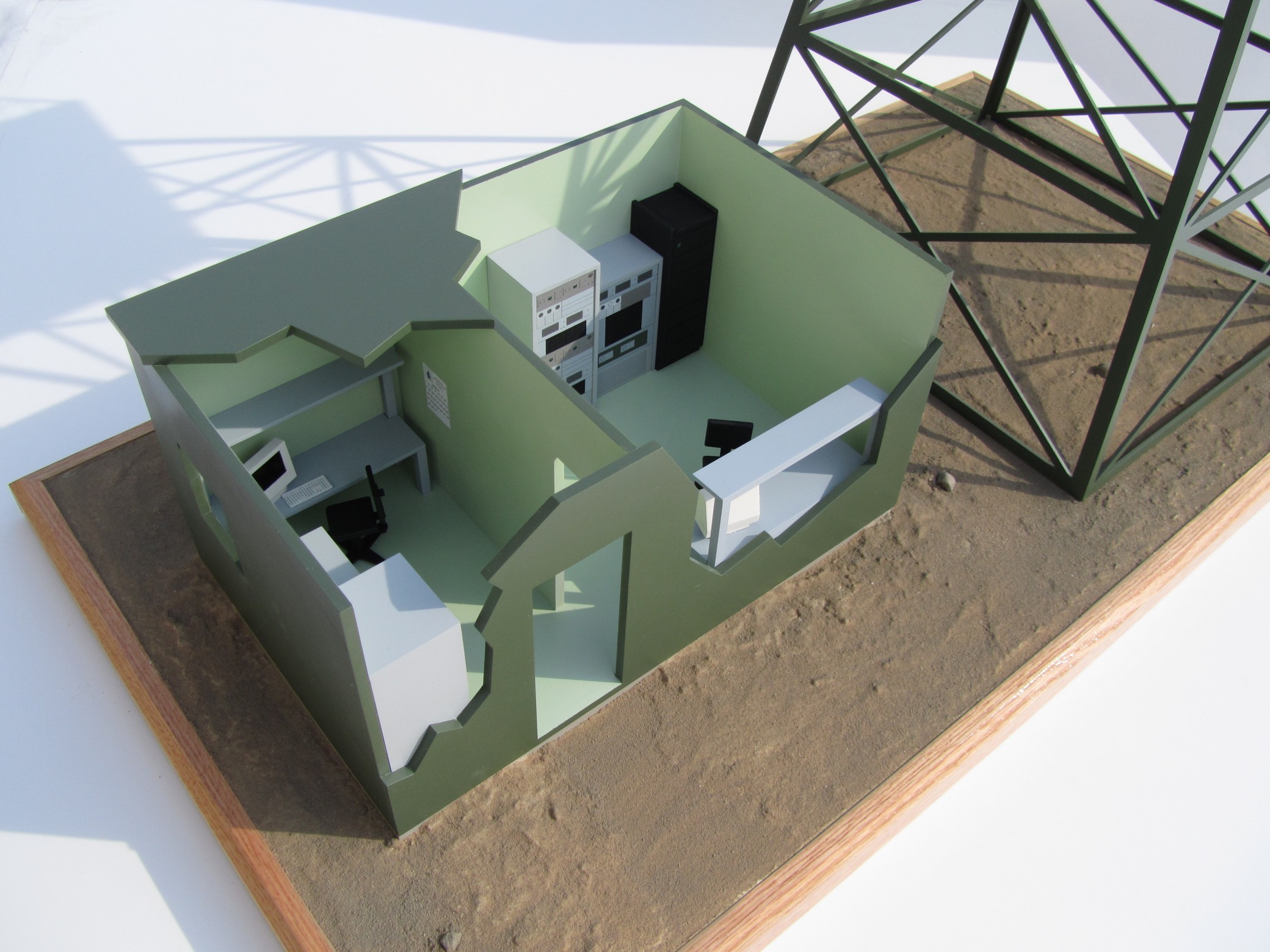

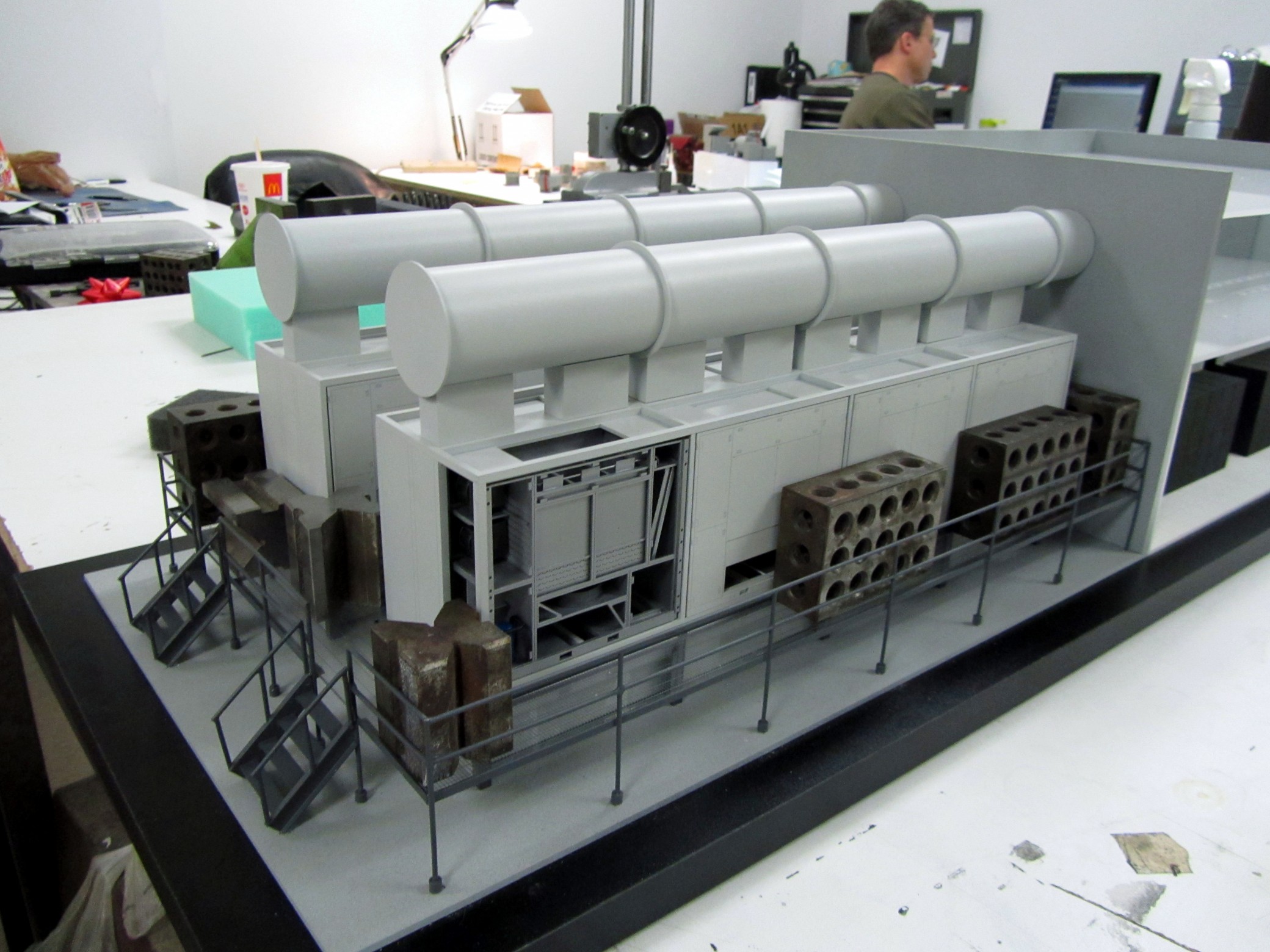

A trade show booth should draw potential customers in to explore, interact with, learn about and bond with your product. What better way to meet these goals than with a scale model of your product? A trade show model can represent your design with the utmost accuracy while drawing attention to the features you want to emphasize.

Considerations:

- It’s often easier to transport a scale model than the product itself, and costs less.

- Your scale model can be touched and examined close up to see how it functions.

- A demonstration of your working model draws customers in to interact personally with your product.

- A 3D model is vision friendly – not everyone can imagine 2D objects in space.

- Cutaways, see-through design, high impact colors and working parts draw attention to your product’s special features.

- Custom cases are provided to house and transport your model safely to various shows.

Everyone loves models, making them natural magnets at trade shows. Customers are drawn to these replicas more than the actual product, sparking curiosity and interest in what you have to offer. Interacting with a scale trade show model creates a lasting impression that can translate into more sales.