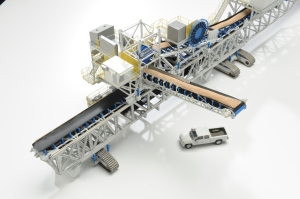

Shipping containers are one of those items you take for granted in life. The intermodal container or “sea can” is a reusable steel box with standard measurements that transports all types of goods around the world. Their universal appeal comes from the ability to transfer from sea to rail to road without having to take the contents out along the way.

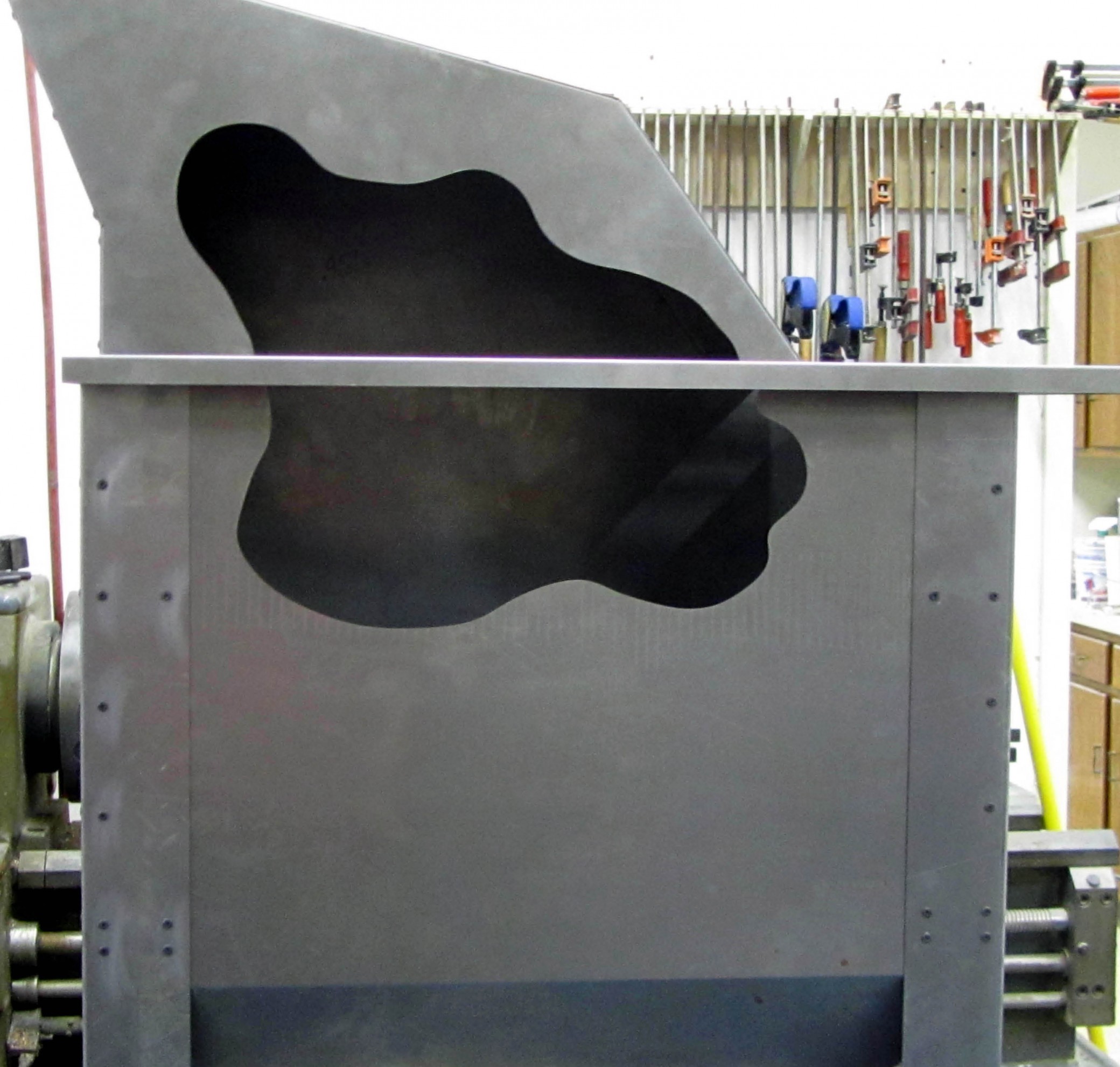

There are tens of millions of these containers world-wide. Most of the containers are 8 ft wide by 8 ft high. Lengths vary from 20 footers to 56 feet long, with corrugated steel walls and a door at one end. They can be stacked on top of each other – all 8 corners have fasteners – and can carry over 20 tons of product each. Each container is marked with a BIC code to identify ownership.

Because of their relative ubiquitousness, and the fact that it takes so much energy to melt down 8,000 pounds of steel, these containers are being given second lives. An entire industry has sprung up with creative ways to reuse these containers that would otherwise be languishing in shipyards at the end of their useful shipping lives. Twenty footers in particular are in plentiful supply, as shippers have moved on to larger sizes over the years.

The most obvious second use for a shipping container is housing. Many architects have created eye-catching, unique urban designs with the 20 foot container as their building block of choice. Other companies are focusing on 3 bedroom, 2.5 bath designs for USA consumers who find the reusable aspect appealing & want lots of square footage. Even more practical is the use of one or two containers to make reasonably sized homes for places and people around the world who need or prefer a smaller footprint.

The use of shipping containers as modular units in the building process is seen as an upcycling of materials. Not only does it cost less to adapt these units than it does to melt them down for materials, but leaving the units in their original state provides a stronger structure than conventional housing frames. Not just limited to housing, containers are being used for office space, retail buildings, museums and even works of art.

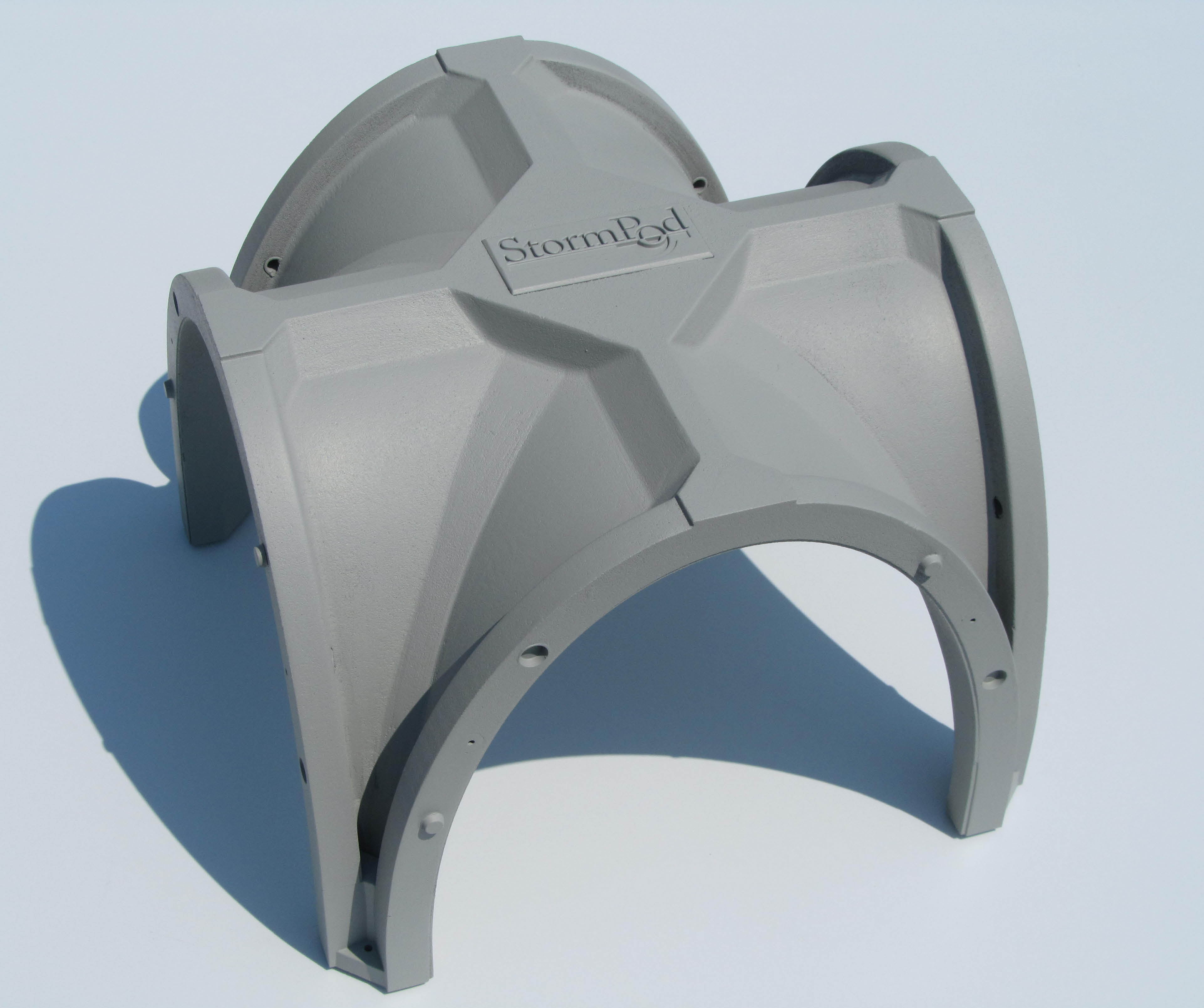

An off shoot of the intermodal shipping container is the expandable shelter concept. These modular units are used for deployment to situations world-wide that can benefit from ready-made, pop open, adaptable shelters. Shipped just like an intermodal container, these spaces then open up, or expand, to offer support services in the event of natural disasters or other types of emergencies. An excellent example of this are the ESS units offered by SAIC.

Intermodal containers are increasingly the focus of businesses looking to create a unique shelter out of a familiar design. Their modular shape, inherent portability, structural soundness and availability make these containers an intriguing concept to design from and build with.

Click Here for an interesting pictorial of shipping containers that are lost at sea.