Often times in the model making business we are asked to sign a Non Disclosure Agreement (NDA) with a client. NDA’s are legal agreements that give protection and reassurance that the information exchanged during a model build will not be shared, or disclosed, with a third-party. The document is usually initiated, or provided by the client (although we have our own generic version we offer) and is often the first step in the quote solicitation process.

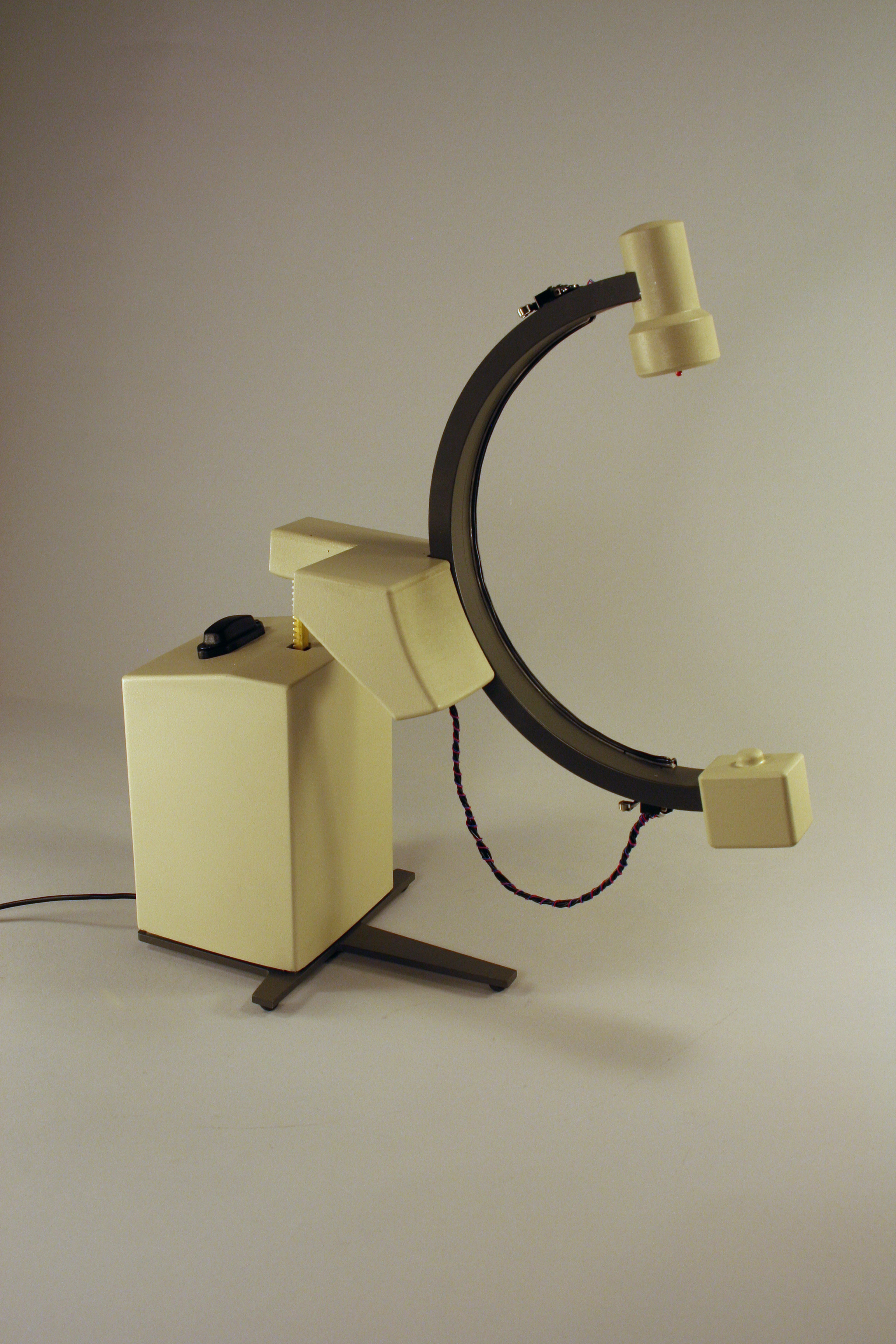

Detailed diagrams, CAD drawings, measurements, blue prints, photographs, descriptions and other data are being given to our model makers in order to facilitate the fabrication of a highly accurate and realistic replication of a product or idea. It is important that our clients feel certain that the exchange of information be used for the sole purpose of providing a quality model that meets or exceeds their specific requirements.

Non-disclosure agreements, sometimes referred to as confidentiality agreements, can cover a wide variety of items that are to be kept confidential and may include such things as customer lists, business practices and financial information, along with the more typical documents that are shared with model shops in order to complete a scale model project. The document also specifies the disclosure period to be covered, the length of time the agreement is binding and the exclusions to what needs to be kept confidential. Exclusions usually refer to information that is publicly available and that which has been obtained through other sources.

Another common portion of an NDA is the need to exercise reasonable efforts to keep the shared information secure and to limit its exposure only to those people who need to know it in order to complete the job.

The reasons for NDA’s are as varied as the terms covered in their pages. An obvious circumstance is when we make a prototype of someone’s patented idea. Often we suggest the NDA ourselves with inventors, knowing that this is an important first step in the process of discussing their innovation.

Frequently our model shop deals with military clients who require additional levels of security. ITAR is a group of government regulations pertaining to defense-related information, services and material. For national security purposes ITAR controlled projects cannot be shared with non-U.S. citizens. Sometimes the engineering information of the project is ITAR controlled, but the end product is not, which means we can share, for instance, a picture of the finished model on our website.

Beyond NDA’s and ITAR controlled projects, there are clients who simply ask us not to share the finished model or the fabrication process on our website, blog or other promotional materials. Often it is simply a matter of timing. Some client wants to keep a new product private until it is officially unveiled at a particular sales event. Another example would be a prop or scale model that we have provided for an exhibit firm, where the design rights reside with them.

In lieu of a formal agreement, KiwiMill has a general policy of not sharing a finished product until it has been shipped and received by our client. Also, if the model is to be unveiled at a trade show, or introduced at a particular sales event, we wait until that event has passed before we publicly post it. While many clients welcome the publicity, and understand the need for self-promotion, we understand that there are a myriad of reasons we may be asked not to divulge finished work.