Like most scale model shops, KiwiMill prepares free-of-charge custom model quotes to anyone inquiring about a project, big or small. Sometimes we give ballpark figures over the phone or email, based on basic information about model purpose, design, size and detail level. These quick estimates can be given for model projects that are similar to ones we have done in the recent past. Initial rough estimates can help identify whether there is a sufficient budget to proceed with a formal written quote.

Most custom scale model inquiries go through a lengthier process to determine the costs involved. First, there’s an exchange of ideas and information with the client, then a bit of research and brainstorming, culminating in a formal, written quote. The quote usually spells out what will be provided by the model makers – over all design, materials, functionality, details, accessories, finishes, and any mounting, bases and crating options included. It also addresses timing and what is required from the client to start the job in terms of data and initial financial investment.

Before generating a formal quote, our sales staff addresses the inquiry: receiving the request, asking clarifying questions, and collecting any drawings, photos or additional documentation provided by the client. The more information that can be gathered about a project, the more detailed and accurate the quote will be. This initial exchange goes very quickly, as the goal is to get the project in the hands of our model makers to assess as soon as possible.

KiwiMill likes to connect potential projects with a model maker fairly early on in the quote process. Talking to an actual model maker has benefits for both the client and the model shop. First, a model maker can help clarify the scope of the project. By talking with a client, our model makers are able to understand what the model is required to do, and in many cases, help determine what the best approach is to meeting those goals. Clients sometimes know exactly what they are looking for in a scale model, but more often than not, an exchange of ideas helps narrow down the options to one that best fits the client’s needs and budget.

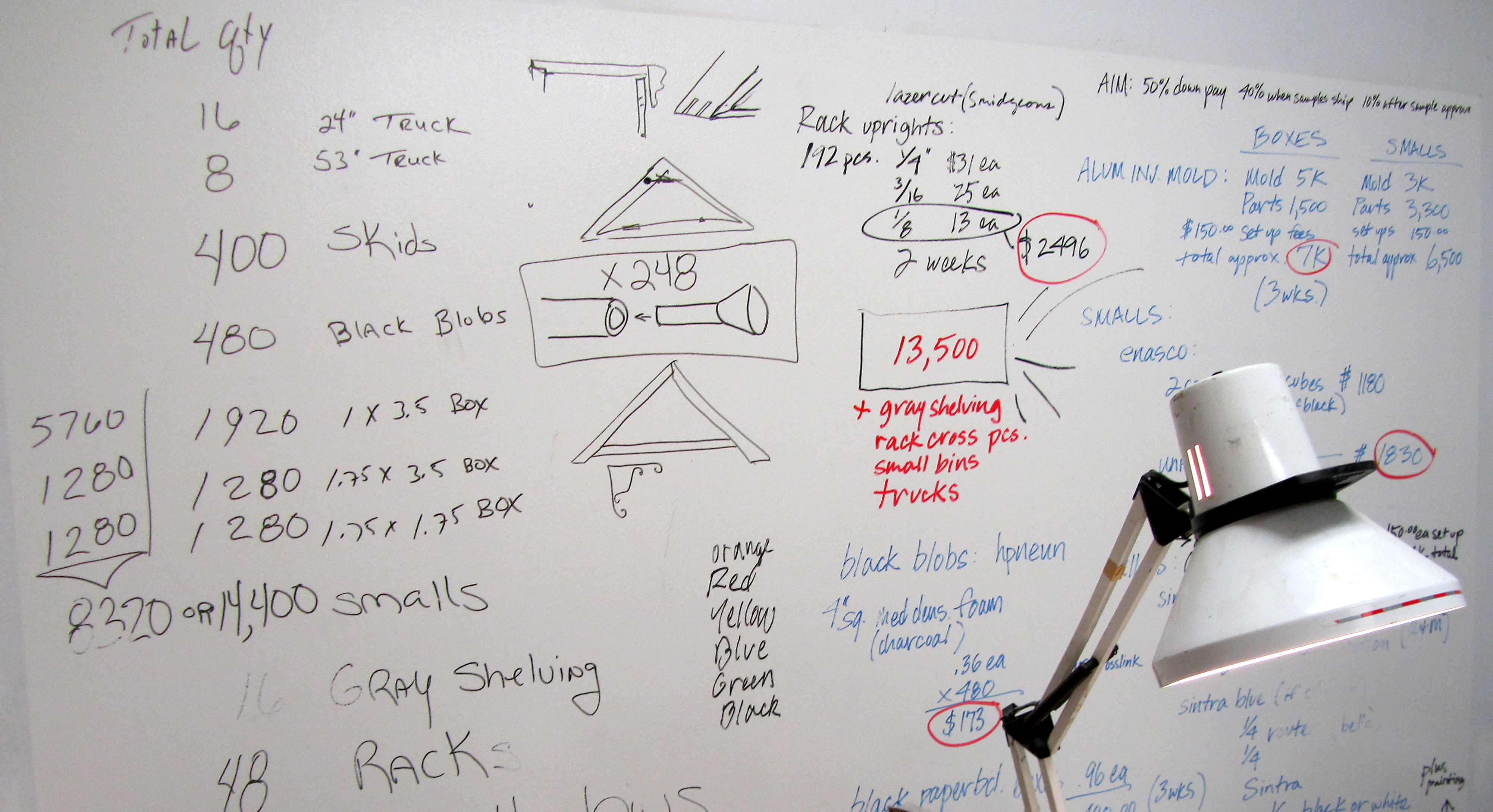

Secondly, our model makers can begin thinking about how they would go about the build of a custom model as they talk with the client about their project. This initial thought process will aid them when it comes time to prepare the actual quote. There is no magic formula used at KiwiMill for generating quotes. Each project is given careful consideration in terms of materials used, fabrication methods chosen, size and complexity of the model, and the engineering of moving parts or other special effects. Another major consideration is whether parts for the model will need to be drawn up in a CAD program, before construction can start. Timing may be a factor as well; if the job needs to be rushed, then vendor supplies and overtime costs need to be considered.

A detailed quote can be prepared after the project is defined, the accompanying documents are studied, availability of materials are researched and fabrication methods are decided upon. This process may sound complex, but it assures our client that what they are getting is what they expected and desired. It also does not need to take up a lot of time. We pride ourselves on getting quotes out very quickly, without sacrificing the attention to detail and customization of each project. Well defined, personalized and accurate quotes are a service we are happy provide to each and every one of our potential customers as an initial sign of our commitment to quality service and performance.