A little talked about aspect of a model maker’s job is to figure out how to pack and ship a finished scale model. No matter how intricate and difficult a build might be, nothing compares to the challenge of getting a model safely to the client in one piece. Scale models can be delicate works of art (though certainly not all of them are) and white glove handling by a dedicated carrier is not always feasable. Shipping companies like Fed Ex and UPS are reasonably priced but do not generally ensure (or insure) that models will arrive unscathed. It’s up to the model maker to give as much thought to the way a scale model will be packed as he has to its design and construction. A project isn’t complete until you get word that the model has been received undamaged.

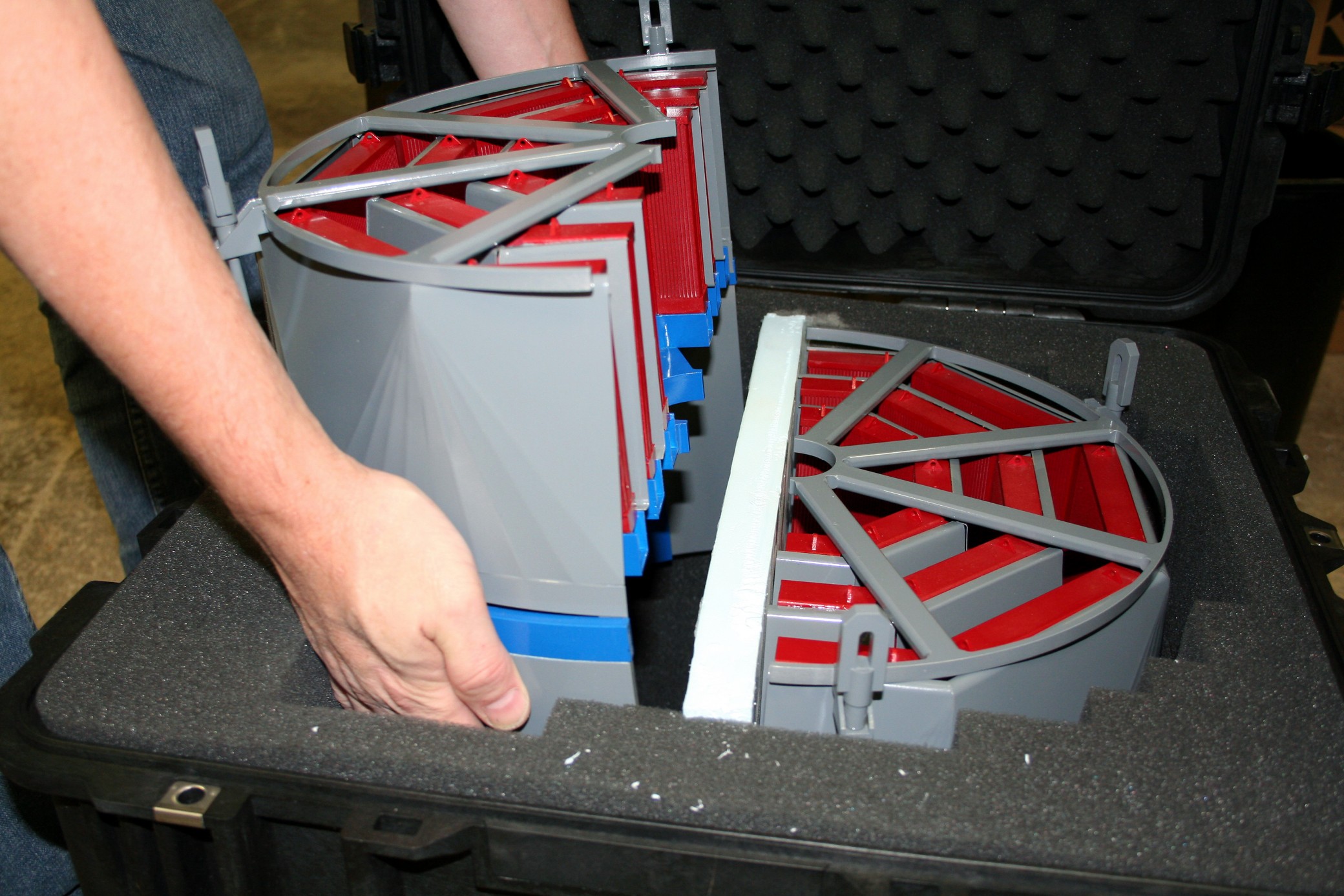

Different packing methods are used for different types of scale models. Smaller projects (under 2×3 ft) are usually packed in premade hard shell boxes called Pelican cases. They come with solid foam inserts that are then carved to fit the model snugly inside. Similar to how a camera or cell phone is sometimes packed when you buy it at a retail store.

Some models are not as hardy and will be unable to lay in the foam openings without damage. These projects are often secured at their base to a crate and the rest of the model is encased in a protective shell and wrapped securely with packing tape. Mummified in a way.

Some crates are built in the model shop, particularly for bigger pieces. Wood crates were custom made for these trade show models, secured on shelves with screws. A local courier then transported the crates to the client.

A scale model might be delivered by the model making company itself, anchored by way of wooden blocks and screws to the bottom of a truck floor. Some common carriers may pick up a model on a skid or pallet, depending on its over all size. Often the shipper is UPS or Fed Ex. With these carriers, there is a chance of the model being dropped, or otherwise roughly handled and occasionally a project will need to be returned for repairs or the model makers will go on site to fix damage in transit. It’s easily one of the most frustrating parts of the job, but skilled model makers know exactly how to repair their work.