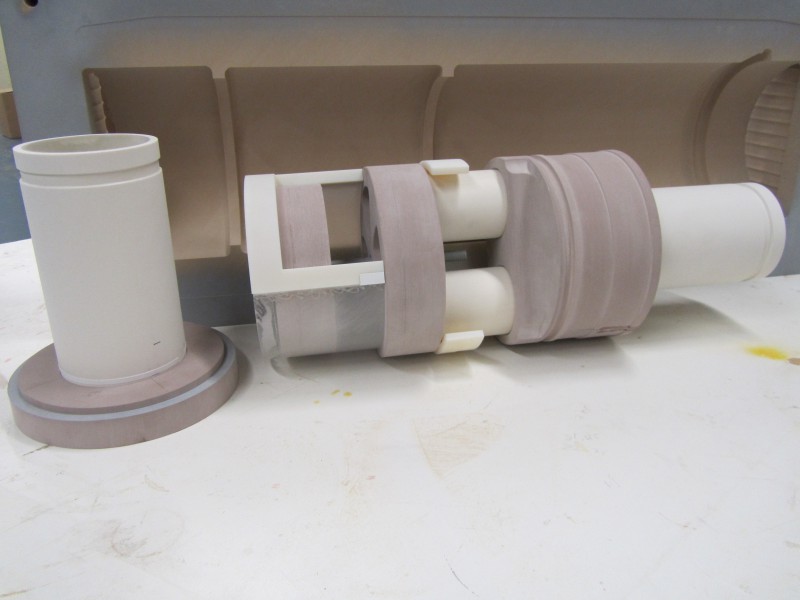

A few weeks ago, KiwiMill finished another cutaway model. Model maker Mike created the 3D files necessary to 3D print some of the smaller, intricate parts. Meanwhile model maker Brian drew up parts for the CNC router to carve out big hunks of tooling board for the outer shells of the cutaway model. He also created files for the CNC mill, which made the patterned holes on some of the interior parts of the model.

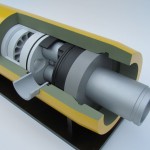

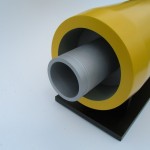

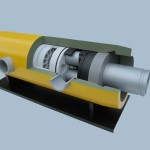

The interesting thing about cutaway models is the glimpse into the inner workings of a product. In this case, the cutaway model has intriguing designs that make for a beautiful reveal. Painting each component a slightly different shade in the cutaway portion of the model further highlight the features. Of course, the signature company color on the exterior of the product attracts attention as well.

Take a look at the process: