It’s been over two years since I’ve started spending time with model makers, and I am still struck by the variety of mediums they work with. Especially since I do the ordering for them!

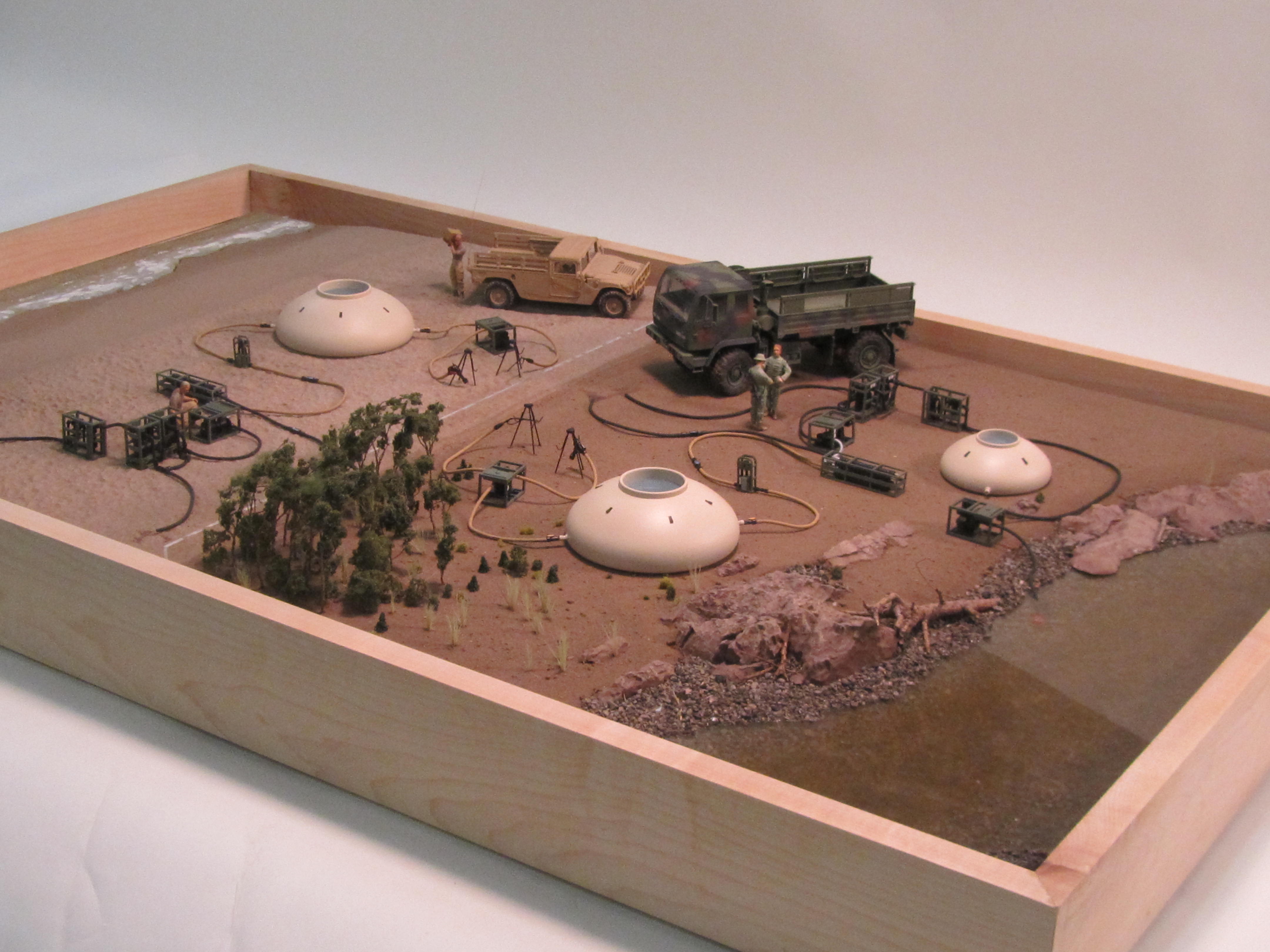

Model makers who make custom models have a stunning variety of material they must be able to construct with, and just as many techniques to go along with that. Depending on the type of model – architectural, trade show, military, museum – and its purpose: sales, display, training, fundraising, etc., the actual substances used to create a model vary.

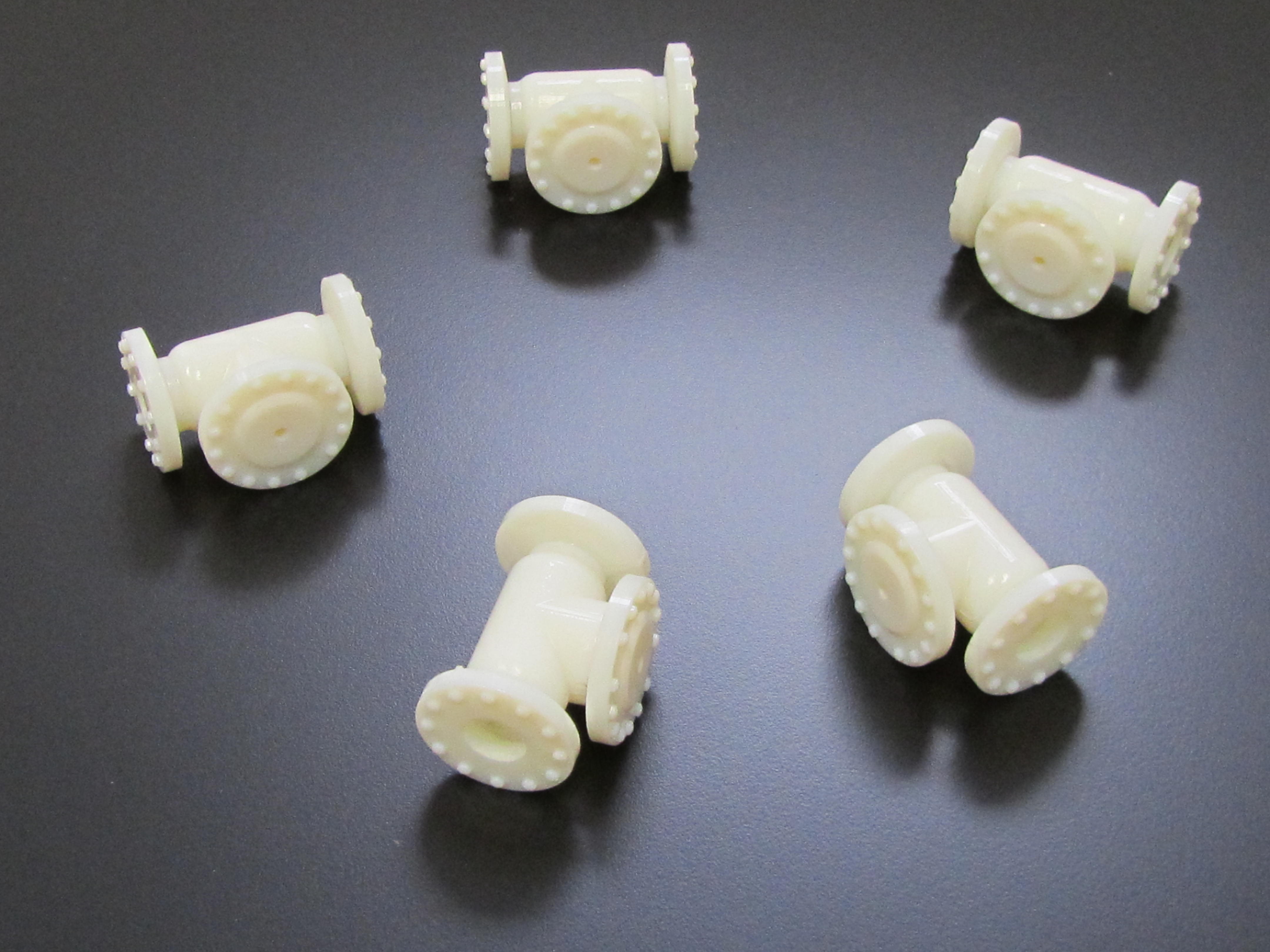

Our model shop works with all types of wood, several types of plastic, a variety of metals, molding compounds – even fabric. Just in the plastic category alone there are several different types, each with its own properties: ABS which is more resilient, acrylic which cuts beautifully on the laser but can break, resin which is the liquid plastic that the 3D printer uses, and styrene – an easily bonded staple of architectural models.

When determining what material to build with, a model maker has to decide what properties are best suited for the purpose intended. If the model will be displayed in a clear box and never touched, then delicate, intricate and the most realistic looking materials can be used. This is rare.

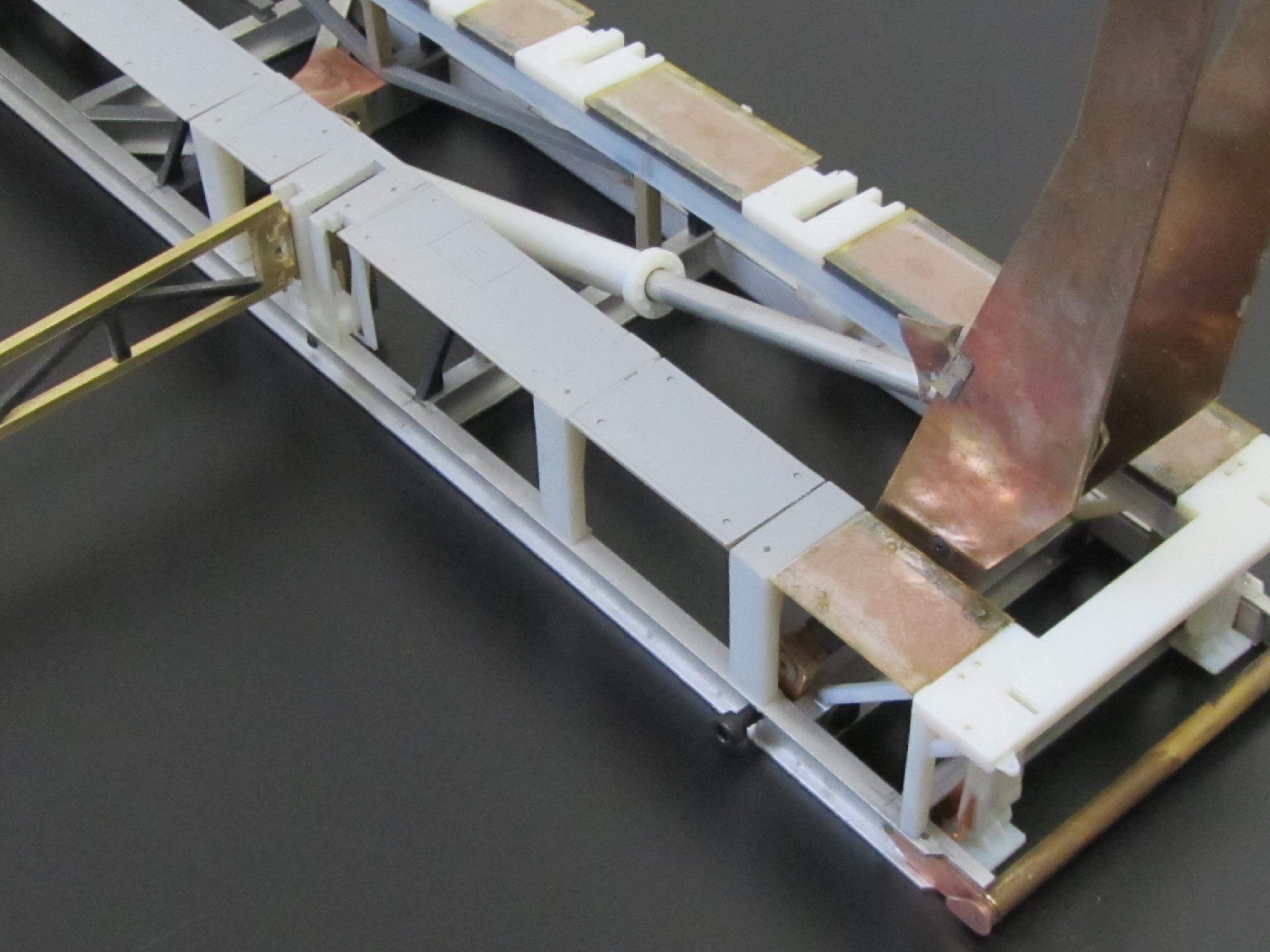

Most of our models are meant to be touched and handled by the viewer and need to be built with substances that can hold up to this kind of treatment. Often times this means a mixture of different plastics and metals. The metal ends up providing a solid skeleton for the model that more detailed pieces can be “hung” from.

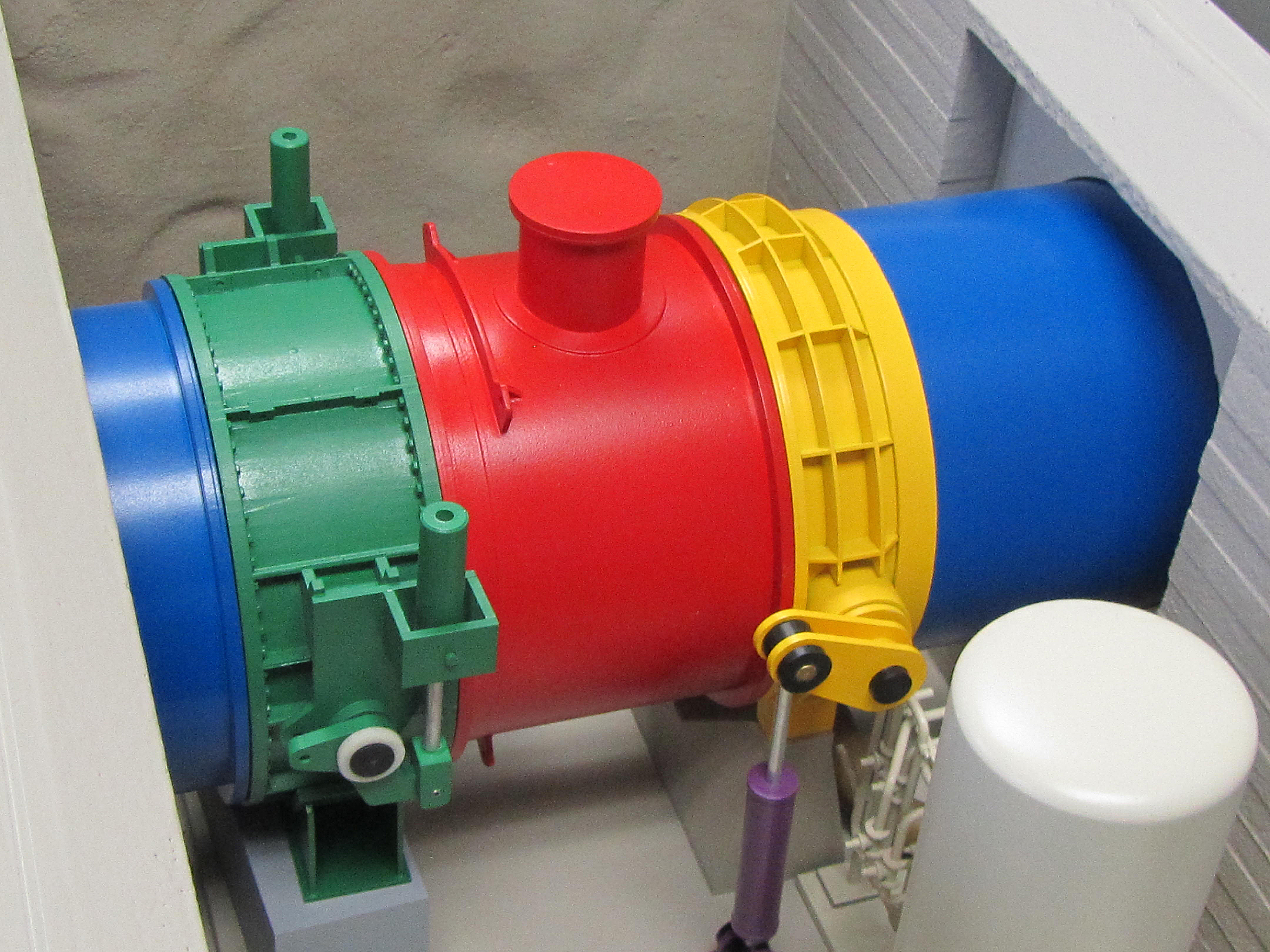

At the extreme end of durability are models that must provide motion, simulate movement or light up. These working models require material that can withstand the friction, and sometimes heat, involved in the moving parts. It may include pulleys, actuators, motors, gears, or electronics that need to be properly housed in the correct materials.

Besides knowing what material to use for which model, a model maker needs to understand how to cut, shape, and cover the chosen substance. Paint doesn’t cover every material the same way. It’s also important to choose the correct fastening method. A model is usually made up of many parts, each of which not only needs to be accurately formed and covered with a properly adhering finish, but then has to be securely attached to the model as a whole.

Knowledge of all the different types of materials that may go into any given model, takes time and practice. Successful model makers are well versed in the various fabrication choices, methods and techniques that go into a custom model. They get this way by actual immersion in the craft.