One of the more appealing characteristics of model making is the excitement generated around each new project. Most model makers appreciate the fact that their work is varied. Each assignment brings with it research, skills, materials and building techniques that were not necessarily used on the last job. Each time a model shop moves on to the next project, it’s a fresh start.

So exactly how does a model maker approach an assignment once the sales staff brings in a new job? First, as much information as possible is gathered about the model. Most importantly, what is the purpose of the model? What will it be used for? Sales tool, developer’s presentation, instructional or educational purposes, visual impact? How many models are needed? How big or tiny will the models be? (Scale).What level of detail does the client want shown on the model?

This beginning stage of the project also means gathering up as much information as possible about the physical details of the item being modeled. This can include photographs, sketches, blueprints, 3D drawings, or the real object itself. It often involves internet research, interpretation and forensic-like piecing together of missing details.

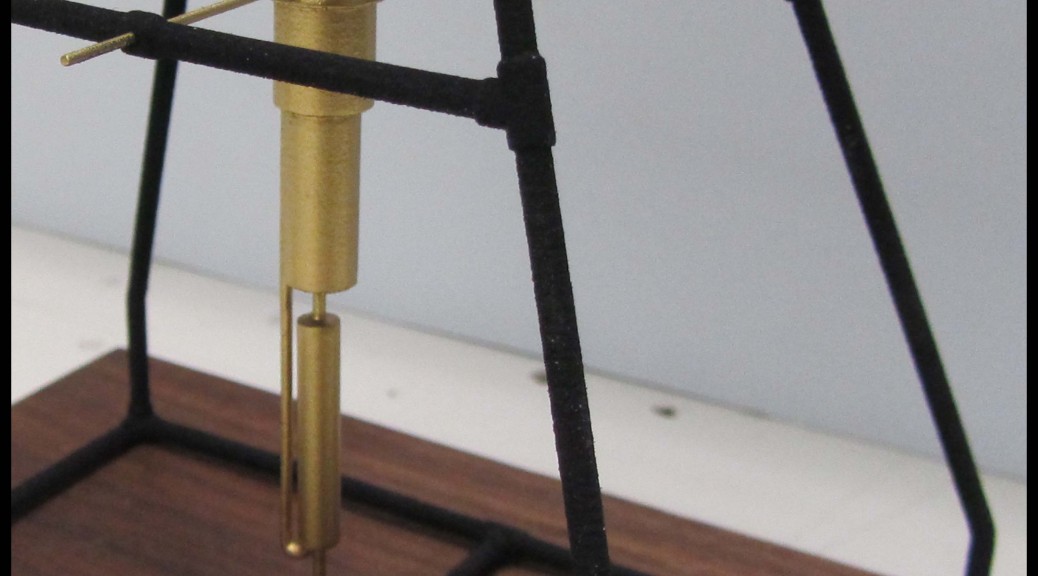

As this information gathering stage is being completed, the model maker begins to visualize the finished product in his head as a whole. What will it look like when completed? Then he mentally takes the model apart piece by piece and begins to imagine what materials will be used to make each part. Reversing the process, the model maker reassembles the project in his head, determining how each piece will be fastened together – glue, rivets, solder. Brainstorming meetings, sketches or detailed CAD drawings might be used to aid this pre-assembly/reassembly stage.

Then the model maker has to think about the order the parts should be made in. What sub-assemblies need to be built? How will the parts be grouped for painting? Once the individual assembly jobs are assigned to different model makers, it’s time to get started on the actual building of the model. Active construction is what model makers are best at, but throughout the process, a well trained mind for research, 3D visualizations, and problem solving skills is essential.

http://www.nasa.gov/sites/default/files/thumbnails/image/robert_h_goddard_and_liquid_fueled_rocket_1926.jpg

http://www.nasa.gov/sites/default/files/thumbnails/image/robert_h_goddard_and_liquid_fueled_rocket_1926.jpg