Some scale model shops specialize in particular types of models. Architectural model making is a common type of specialization, as well ship building or airplanes, here in the United States. Model trains would be another example of builders focusing on one specific genre.

KiwiMill, like many of today’s scale model shops, has chosen to market to a variety of industries in need of custom model designs. Custom model requests may come from the military, land developers, manufacturers, advertising agencies, product developers, private collectors, the medical field, museum and exhibit companies. Really, the possible sources for clients are endless.

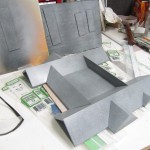

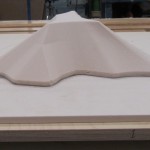

Along with the variety of industries that require scale models, there are various types of models which are commissioned. Trade show models, cut-aways, display models, working models, training models, product models, prototypes and sales models are a few examples of the types of models requested by clients. The purpose of the model – what it is being used for – drives the type of model required, which then informs the model maker as to how to go about the build.

While specialization in a particular type of scale model building has its advantages – stocking materials, investment in fabrication methods, model maker training – at KiwiMill we believe a broad approach is more advantageous. Part of the allure of model making is its custom nature. Master model makers often thrive on the variety and challenge of each new job. Sameness is the antithesis of what many custom model makers are looking for in their work environment. Our model makers work best when presented with something new to build each project.

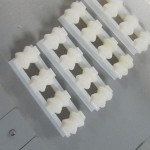

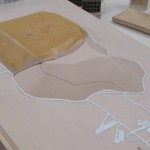

Providing the variety of custom model work that our team thrives on can be a challenge. Marketing to such a wide range of potential customers is daunting. Supplying the machines, tools, software and technology to build all types of custom scale models is an investment. Finding and stocking materials for each new job is an ongoing process. One job may require tooling board and brass piping, while the next project requires a source for fabric or tiny plastic footballs. A little bit of waste in regards to material left overs from previous jobs is to be expected.

Assembling a team of model makers who have the talent, training and abilities to make all kinds of models is important. It hasn’t been difficult for our scale model shop to find the combination of attributes that allow for creations of great depth and breadth. Some of our model makers have over 20 years experience with architectural models. Others have experience with prototypes and product development. Still others are engineers by nature and provide the CAD knowledge and mechanical expertise to draw up model parts and add movement, sound or lights.

The toughest part about deciding to build all types of custom models and not specialize in a particular type, is convincing the general public that we know what we’re doing. Our business is fortunate to have a large portfolio of varied work going back decades that we can share with potential clients. Yet, often we are asked to build a model of something that we haven’t done before. That’s the nature of the business – just about any object known to society can be replicated. It’s impossible to have examples to show for every request made. Reassuring customers that we can build a model of a product that we have never encountered before is part of our job.

What that means is that our satellite models are every bit as sophisticated as our museum dioramas. Our model makers can replicate a military all terrain vehicle as readily as they can recreate a piece of industrial equipment in the form of a cutaway. Not only are our model makers capable of making all types of models, representing all types of industry; they thrive on it.