Today in the shop our model makers are carving foam. That can only mean one thing – besides a mess – a topography model! A topography model depicts the 3D nature of a particular terrain, accurately recording elevation levels and identifying specific land forms.

A topography site plan is used for this project.

The site plan is then transferred to a foam block for carving. While in the past topographic models were layered up, using cork, mat board or foam core, modern techniques use the opposite process. Starting with a foam block, the relief is then carved out of the solid piece with a router. The depth that the router plunges into the foam is determined by the scale being used on the map. Different colored lines on the map represent different elevations. Once the routing is complete the different steps created in the foam are then sanded down to make a smooth transition in elevation levels.

The foam will then be painted, roads glued down and the remaining surface flocked.

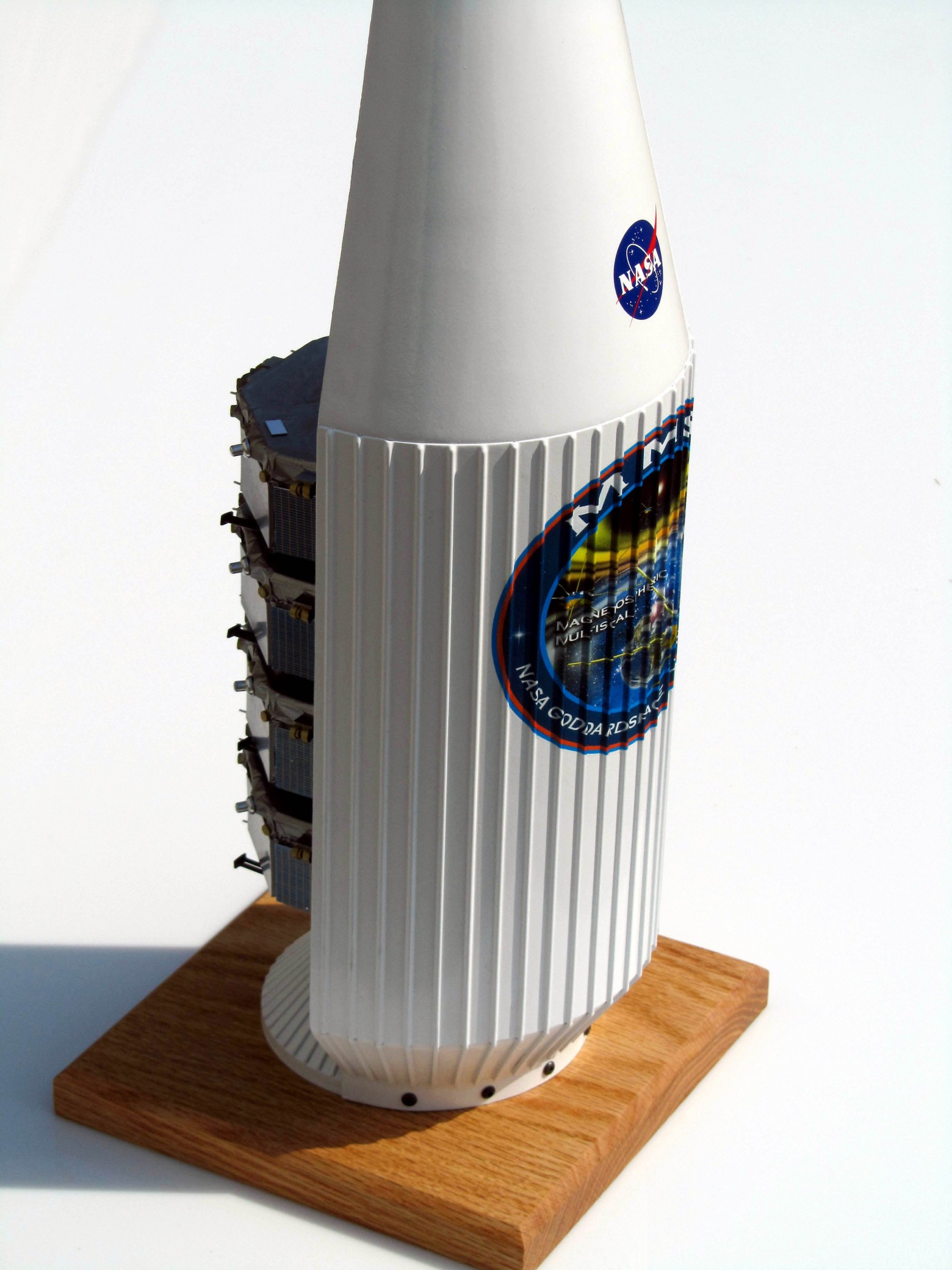

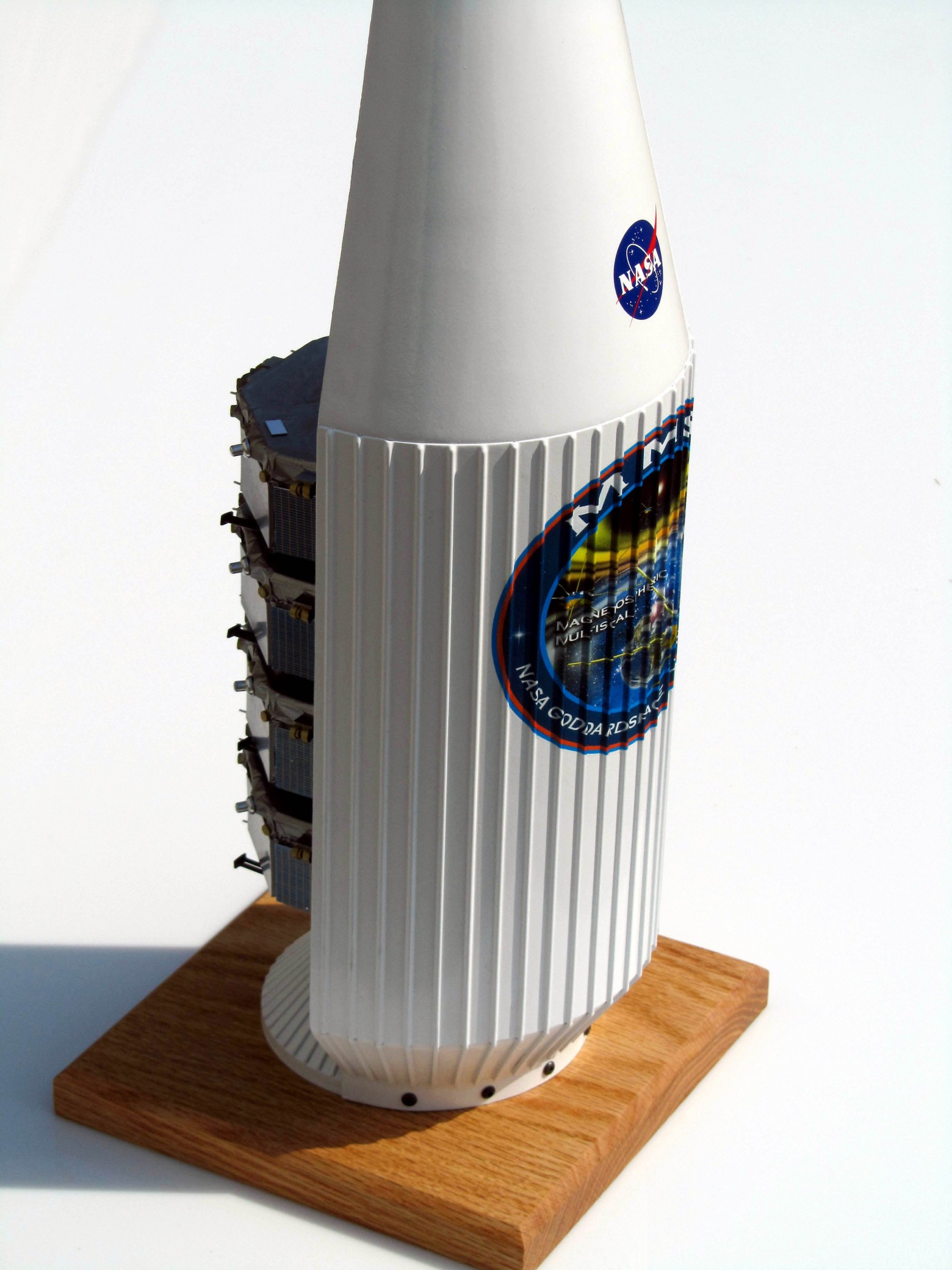

KiwiMill recently shipped out a spacecraft model of the Magnetospheric Multiscale (MMS) mission. This is a NASA launch set for 2014, where 4 identical spacecraft will be sent in a capsule to probe Earth’s magnetosphere. http://mms.gsfc.nasa.gov/.

The cone of the model was vacuum formed and laser cut ribs were later added to the inside. On the outside of the cone, ribbed sheet stock was used. The solar panels are decals. The 4 spacecraft housed inside the cone were molded and cast out of resin, complete with their instruments.

Out the door and on to our client, Carestream. This sales model is 13x its original size. It’s part of a Digital Radiography System used by dentists for x raying teeth.

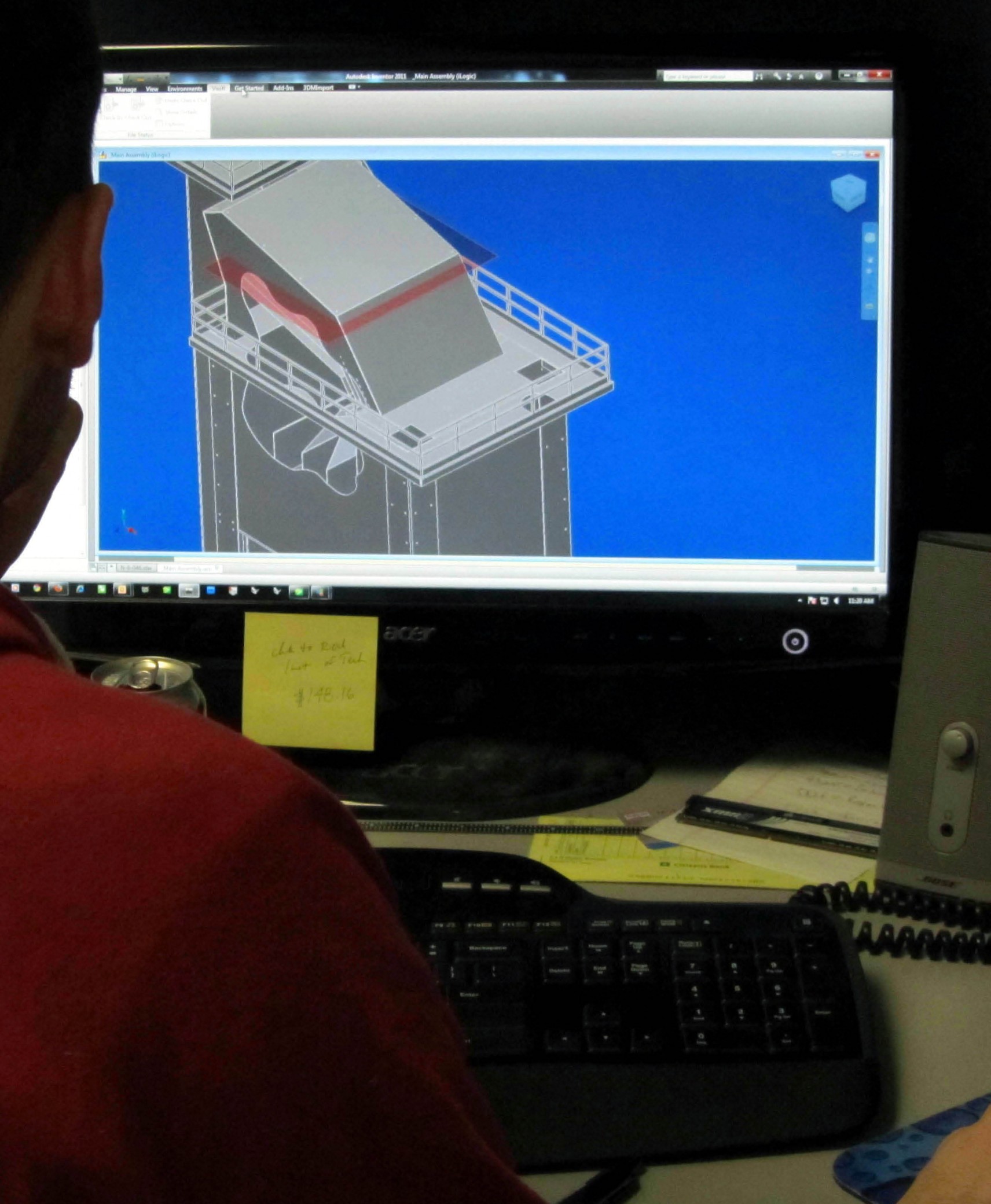

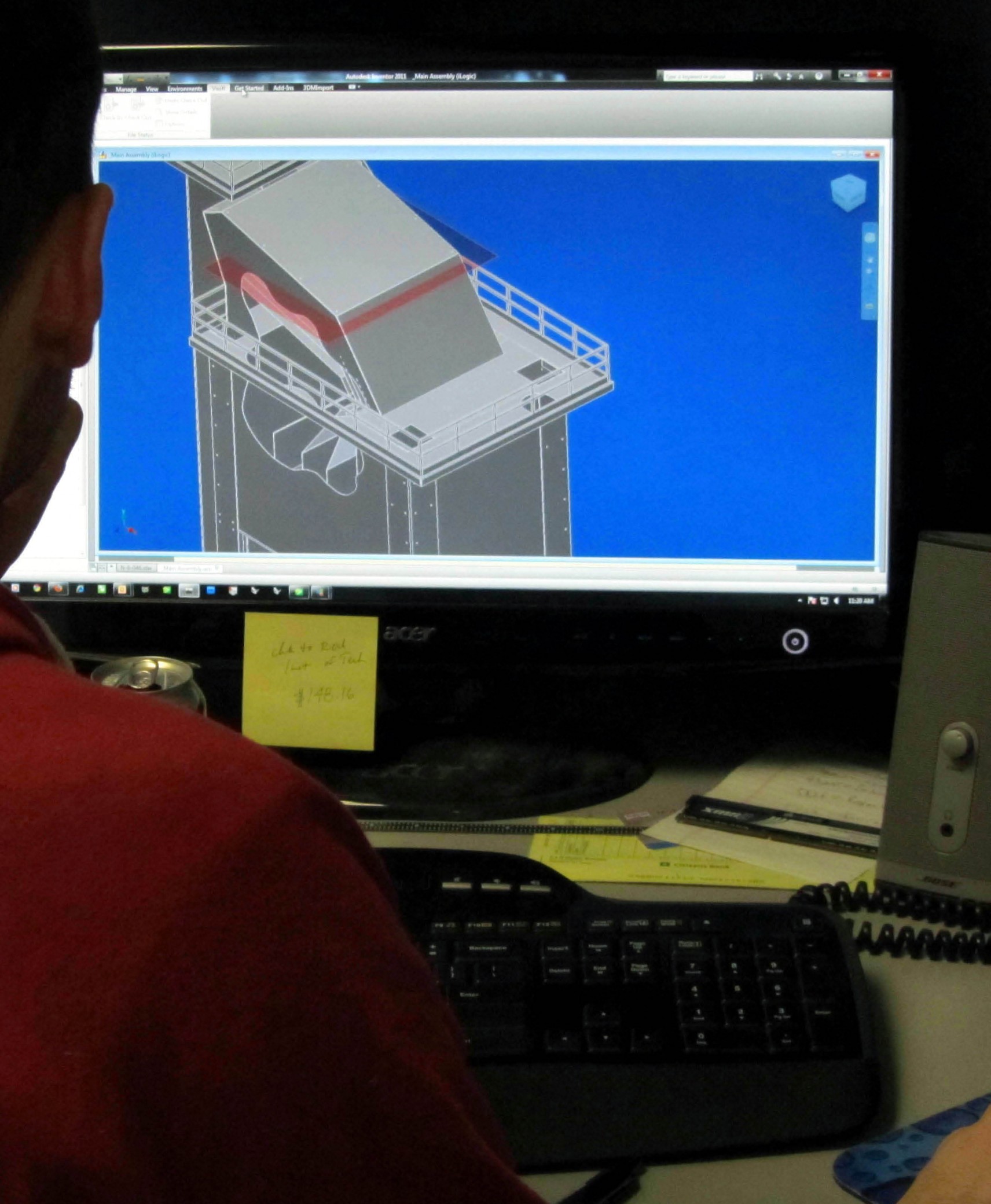

Our shop has been working on a project that involves extensive use of 3D mechanical drawings. The scale model, an asphalt plant, will be 7 feet tall when completed. The size and structure of the scale model requires it to support its own weight and traditional model making materials would not be appropriate. Sheet metal will be used instead, and the parts need to be sent out of the shop to be laser cut and bent.

Model makers typically design a project as they build it, problem solving, adjusting and refining their techniques as they go. As craftspeople, they can transform a rough idea into something both accurate in design and beautiful to behold. The sheet metal parts are being sent to a laser cutter unfamiliar with the project’s nuances, so more precise, documented dimensions are needed.

Using a program called Autodesk Inventor, our model makers have drawn up the sheet metal parts on the computer to be sent to the laser cutter. Then the parts will be bent next door at Clad Industries. The finished pieces will arrive back to the model shop for assembly and detailing. Check back for pictures of the finished scale model!

inside peek @ innovative model makers