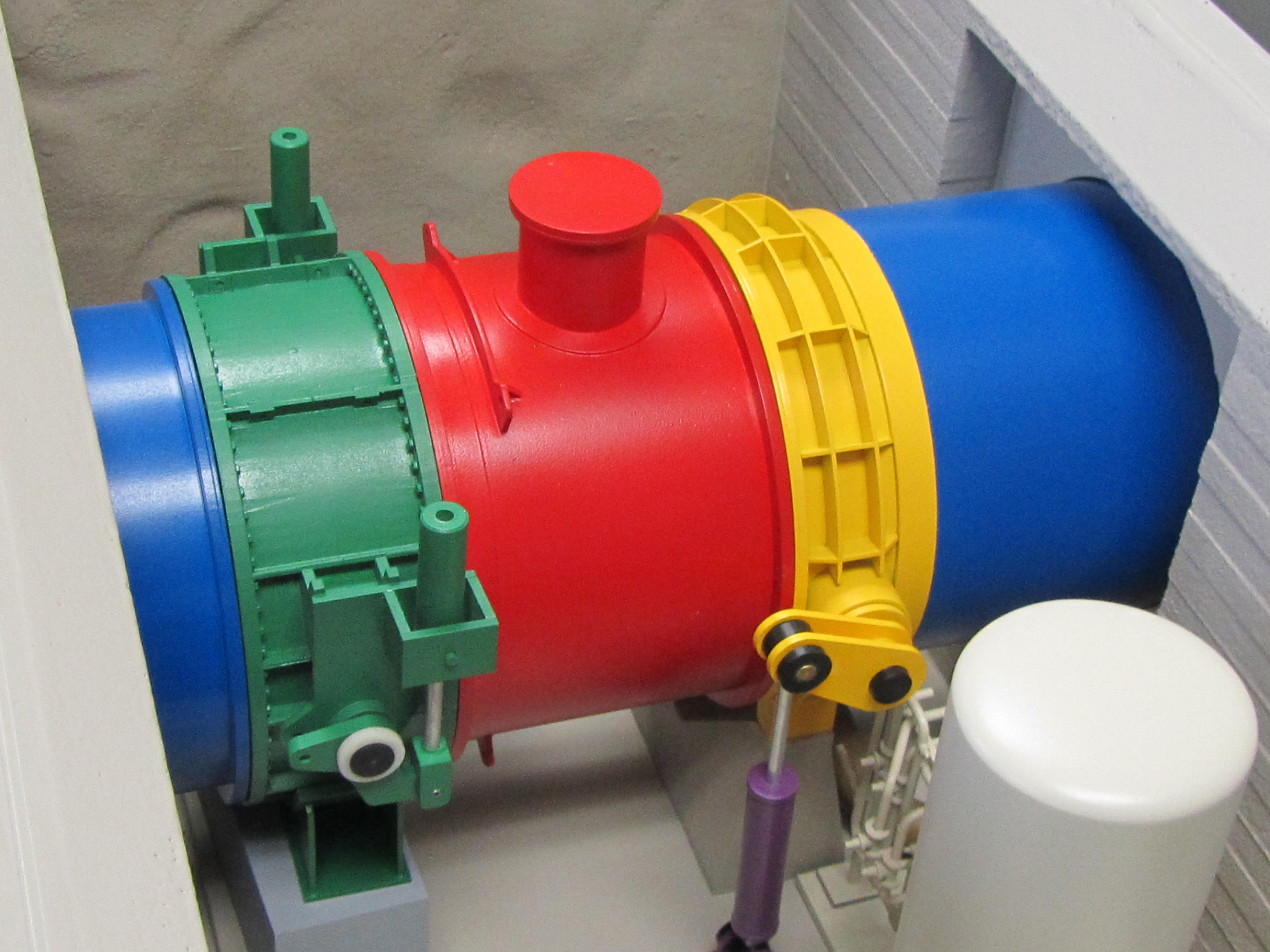

A scale model of an industrial product allows a company to demonstrate its machinery or piece of large equipment using a hands on approach. Having a scale model sets your product apart from the competition that’s relying on a two-dimensional display. A color brochure of a product, or even a video demonstration will not deliver the impact a scale model does. A 3 dimensional model communicates effectively, answering specific questions about your product. It can also highlight the particular features or strengths that you want emphasized. Plus, it’s just plain cool to have a miniature model of your product on hand.

Often an industrial process or piece of machinery is too large, complex or cumbersome to travel between trade shows. A model, on the other hand, is portable while still being instantly recognizable and understood as a replica of your product. No need to worry that the potential client cannot visualize your product accurately from a 2 dimensional drawing or photograph. While nothing can substitute for the real product, a quality replica can be a highly effective alternative. Its physical presence provides direct understanding about what you are offering and translates into a more positive sales experience.

At KiwiMill, our model makers can work with you to provide an accurate, visually pleasing, detailed-as-you-want scale model in a user-friendly scale. Specific features can be emphasized on the model, making it easier for your sales staff to illustrate your product’s uniqueness. Duplicate models can be constructed for multiple shows. Replicas are a cost-effective, engaging option when bringing along the real product is not feasible. No one should go into a presentation without this sales tool in hand!