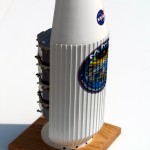

We’re getting ready at the model shop for a new 3D printer. This machine will introduce additive processes for model making designed to increase flexibility and productivity.

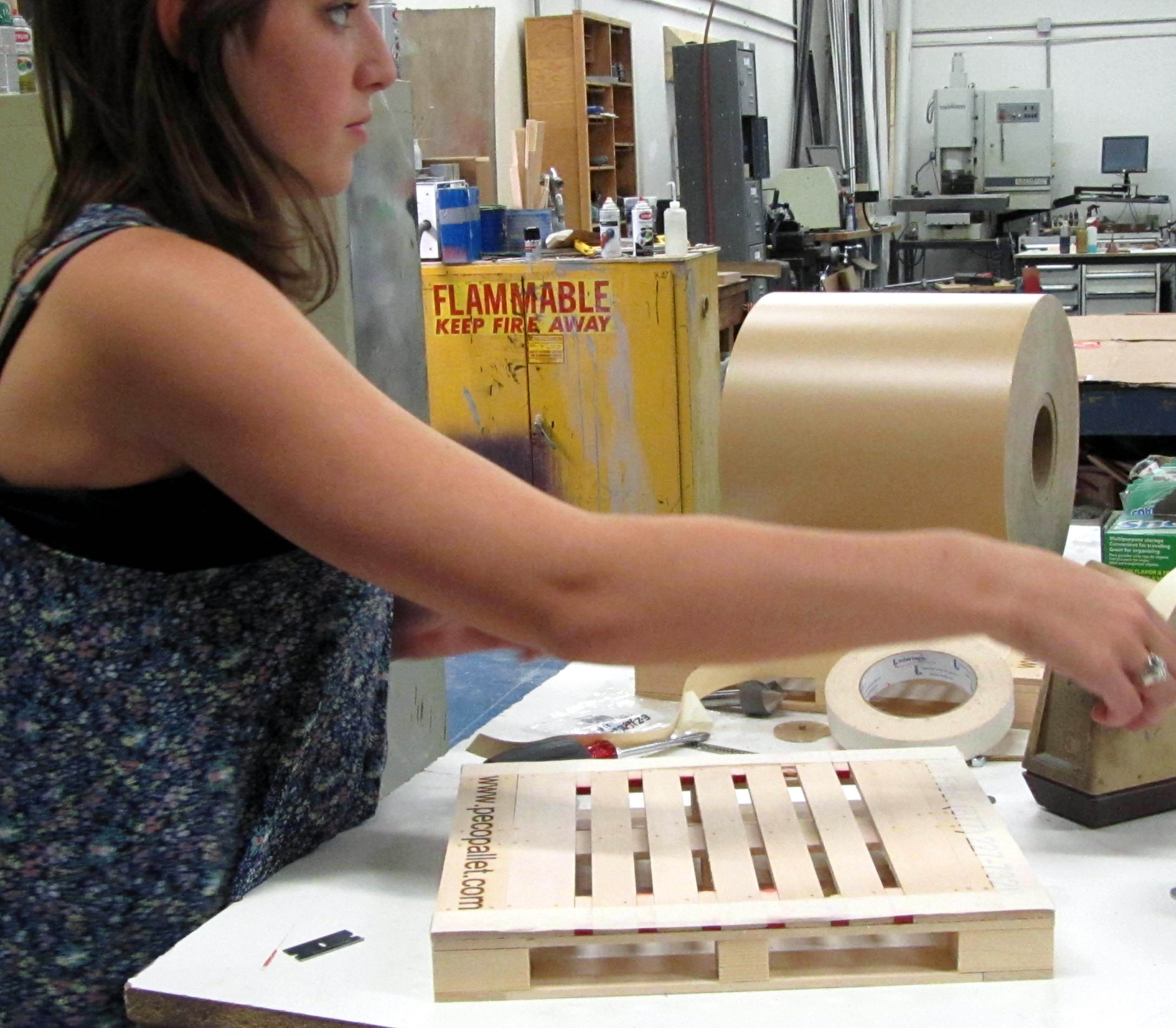

Model making has traditionally been associated with a subtractive method of fabrication. Meaning, model parts are formed by taking something away from a material through carving, sculpting, cutting, sanding or chopping. These extracted parts are then glued together to form the whole model.

Additive methods of model fabrication do the opposite. Instead of sculpting a model out of material by taking away, an object is built up layer by layer. This additive process creates a 3D object from seemingly nothing. A computer image of the desired part is programmed into the 3D printer. The machine then creates a solid object by adding successive layers of material in the desired shape and form.![4339687067_8342a56943[1][1]](http://ammodel.files.wordpress.com/2011/08/4339687067_8342a5694311.jpg?w=199)

The additive method is fast and efficient, vastly reducing the amount of hand’s on work needed to create a model part. The subtractive method can be sped up as well with the addition of computer numerically controlled (CNC) machines, making rote shaping and carving tasks more autonomous.

These technological advancements are welcome additions to the model making shop. They cannot replace craftsmanship, experience and artistry. They’re meant to enhance the fabrication process, freeing up our model makers to put their energy and talents toward more essential and complex tasks.

![5049218531_823aae3c13[1][1]](http://ammodel.files.wordpress.com/2011/08/5049218531_823aae3c1311.jpg?w=300)